Industry information

Company News

- Exploring the Charm of Hyperbolic Aluminum Veneer: The Perfect Combination of Innovation and Art

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer curtain wall, a fashionable outerwear in architecture

- Aluminum veneer: a metal fashion show in modern architecture

- Aluminum veneer: a new favorite in the construction industry. How much do you know about it?

Industry dynamics

- Innovative technology achieves 1.5mm aluminum veneer carving

- Hyperbolic aluminum veneer: the fashionable new darling of the aluminum industry

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

- The Beauty of Customization: Aluminum Veneer, Unique Choice for Personalized Space

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Frequently asked questions

- What are the applications of aluminum veneer in the construction industry and how can they be improved?

- What are the applications of aluminum veneer in the construction industry?

- How to apply aluminum veneer in construction and interior decoration?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What factors will affect the price of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Engineering perforated aluminum veneer creates permanent and durable high-quality building materials

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 27, 2025 00:30:07

- Click:0

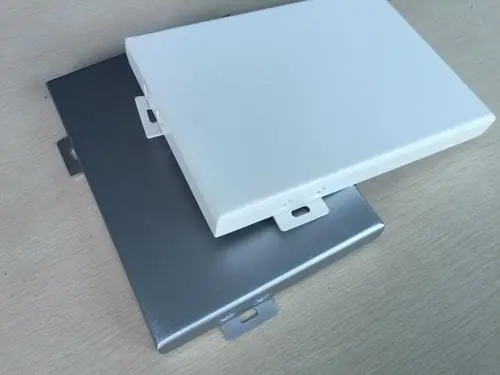

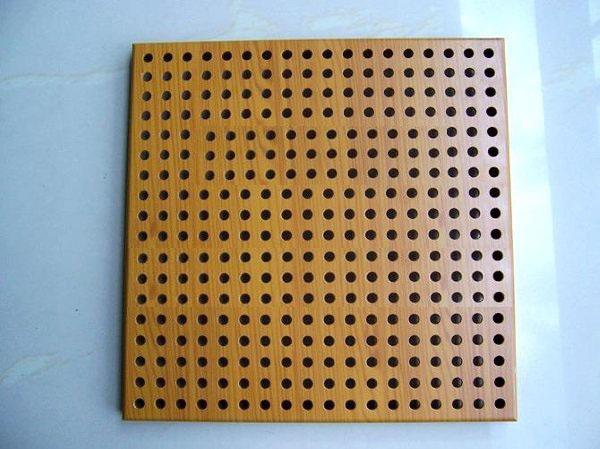

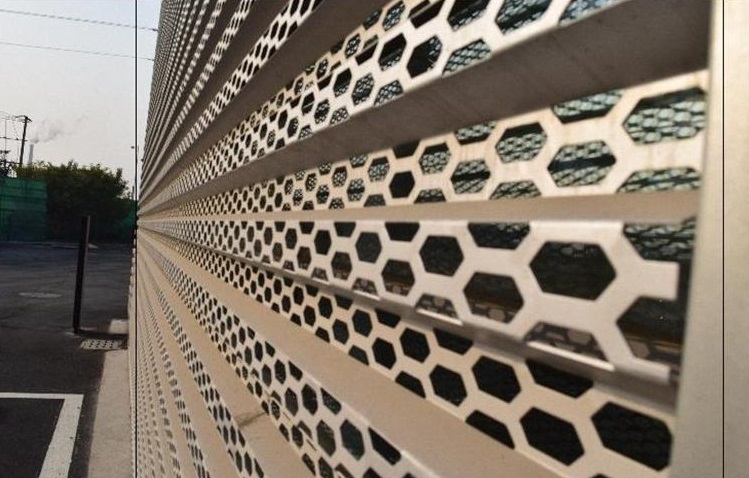

perforationAluminum veneerIt is a common building material that has been widely used in modern architecture. With the increasing demand for building materials, the permanent durability and high quality of perforated aluminum veneer have gradually become a popular choice in the market. This article will provide a detailed introduction on how to create permanent and durable high-quality building materials through perforated aluminum veneers from the following aspects.

1、 Material selection

1. Aluminum alloy material: Aluminum alloy material has the advantages of lightweight, high strength, and corrosion resistance, making it an ideal material for making perforated aluminum veneers.

2. High strength steel: High strength steel has high strength and hardness, can withstand greater loads and impact forces, and is suitable for large-scale engineering fields.

2、 Surface treatment

1. Anodizing treatment: Anodizing treatment can form a dense oxide film on the surface of aluminum veneer, improving its corrosion resistance and hardness.

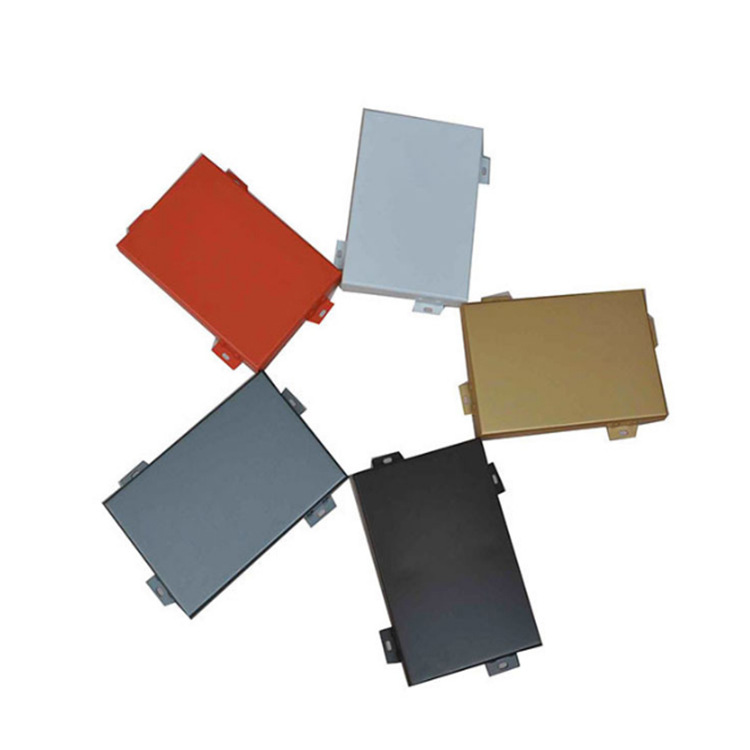

2. Spray treatment: Spray treatment can form a uniform color coating on the surface of aluminum veneer, improving its decorative effect and aesthetics.

3、 Perforation design

1. Reasonable perforation design: The perforation size and quantity of perforated aluminum veneer should be designed according to actual needs to avoid situations where it is too large or too small, which may affect its effectiveness.

2. Accurate perforation position: The perforation position of perforated aluminum veneer should be accurately positioned to avoid deviation or offset, which may affect its overall aesthetics and stability.

4、 Processing technology

1. Adopting advanced processing equipment: Adopting advanced processing equipment can ensure the accuracy and quality of perforated aluminum veneer, while also improving production efficiency and reducing costs.

2. Strict quality control: The quality of every link in the production process should be strictly controlled to ensure the quality and stability of perforated aluminum veneer.

5、 Summary

By selecting high-quality materials, fine surface treatment, reasonable perforation design, advanced processing technology, and strict quality control, permanent and durable high-quality perforated aluminum veneer can be created. This type of building material can not only meet the different requirements of buildings, but also improve the overall aesthetics and practicality of buildings. In practical engineering, suitable perforated aluminum veneers can be selected to achieve better decorative and usage effects. Attention should also be paid to operating in accordance with relevant specifications and standards to ensure the quality and safety of the entire project.

Customer service QQ

Customer service QQ