Industry information

Company News

- Aluminum veneer customization, creating personalized spatial aesthetics

- Unveiling the Secrets Behind the Beauty of Architecture: Aluminum Veneers for Curtain Walls

- Aluminum veneer curtain wall: a lightweight tool for architectural aesthetics

- Aluminum veneer curtain wall, the new favorite of "soft decoration" in architectural art

- Why has aluminum veneer curtain wall become the new favorite of modern architecture?

Industry dynamics

- The environmental concept of customized aluminum veneer: practicing green building and creating a sustainable future

- How to control the color difference of aluminum veneer?

- Light luxury fluorocarbon ceiling aluminum veneer installation guide

- Hyperbolic aluminum veneer: the new darling of modern architecture

- Aluminum veneer: the beauty of architecture, a secret weapon as light as wings!

Frequently asked questions

- What are the types of aluminum veneer?

- What are the applications of aluminum veneer in the construction industry?

- What are the applications of aluminum veneer in the interior decoration industry?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the color difference control standards for aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-08 23:02:42

- Click:0

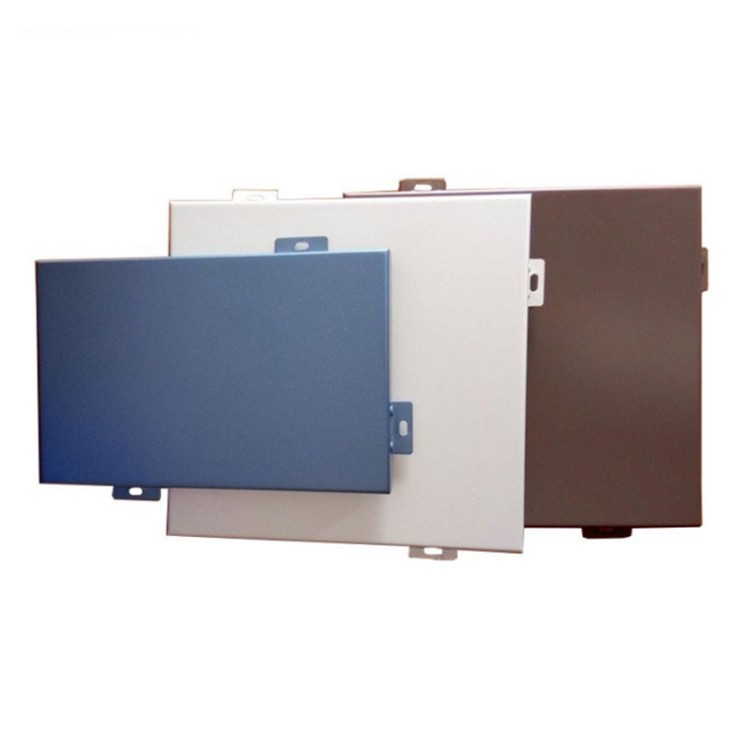

Aluminum veneerIt is a widely used building material, and the consistency of its color is crucial for the overall appearance and quality of the building. Controlling the color difference of aluminum veneer is one of the important steps to ensure product quality. The following will provide a detailed introduction to the color difference control standards for aluminum veneer and how to achieve this goal.

1. Color difference control standard for aluminum veneer

In the production process, in order to ensure the color consistency of aluminum veneer, the following standards are usually adopted:

(1) ISO9001 Quality Management System Certification Standard: This standard requires enterprises to establish a sound quality management system, including raw material procurement, production processes, inspection and testing, to ensure the stability of product quality.

(2) GB/T23443-2017 Standard for Aluminum Veneer for Building Decoration: This standard specifies the requirements for the size, surface treatment, color, and other aspects of aluminum veneer to ensure that the product meets national standards.

(3) JG/T 139-2012 Technical Specification for Aluminum Alloy Sheet for Building Curtain Walls: This standard specifies the technical requirements for aluminum alloy sheet for building curtain walls, including surface treatment, color, hardness, etc., to ensure that the product meets industry standards.

How to control the color difference of aluminum veneer?

To control the color difference of aluminum veneer, the following aspects can be taken into consideration:

(1) Selection of raw materials: Choosing raw materials with the same chemical composition and physical properties can reduce the occurrence of color differences. Raw materials can also be screened and graded to ensure that each batch of raw materials has the same quality.

(2) Optimization of production process: By optimizing the production process, such as controlling spraying temperature, spraying distance, spraying time and other parameters, the uniformity and consistency of aluminum veneer color can be improved.

(3) Inspection and testing methods: By using scientific inspection and testing methods such as visual inspection, spectroscopy, spectrophotometry, etc., color difference problems can be detected and corrected in a timely manner. A strict quality control system can also be established to monitor and record every step to ensure stable product quality.

Controlling the color difference of aluminum veneer is one of the important steps to ensure product quality. By selecting high-quality raw materials, optimizing production processes, and adopting scientific inspection and testing methods, color difference issues can be effectively controlled, and product consistency and reliability can be improved.

Customer service QQ

Customer service QQ