Industry information

Company News

- Fluorocarbon aluminum veneer: the new darling of the construction industry, what do you know about it?

- Customized aluminum veneer, creating personalized space and new fashion

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Hyperbolic aluminum veneer: the fashionable new favorite of modern architecture

- Aluminum veneer curtain wall, a new chapter in architectural art

Industry dynamics

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Unveiling Hyperbolic Aluminum Veneer: The 'Fashion Coat' of Modern Architecture

- Aluminum veneer: the new darling of modern architecture. How much do you know about it?

- Processing and forming technology of curtain wall aluminum veneer

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

Frequently asked questions

- How to apply aluminum veneer in construction and interior decoration?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the applications of aluminum veneer in the construction industry and how can they be improved?

- What are the applications of aluminum veneer in the interior decoration industry?

- What are the applications of aluminum veneer in the construction industry?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the advantages of seamless splicing technology for aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-08 19:55:33

- Click:0

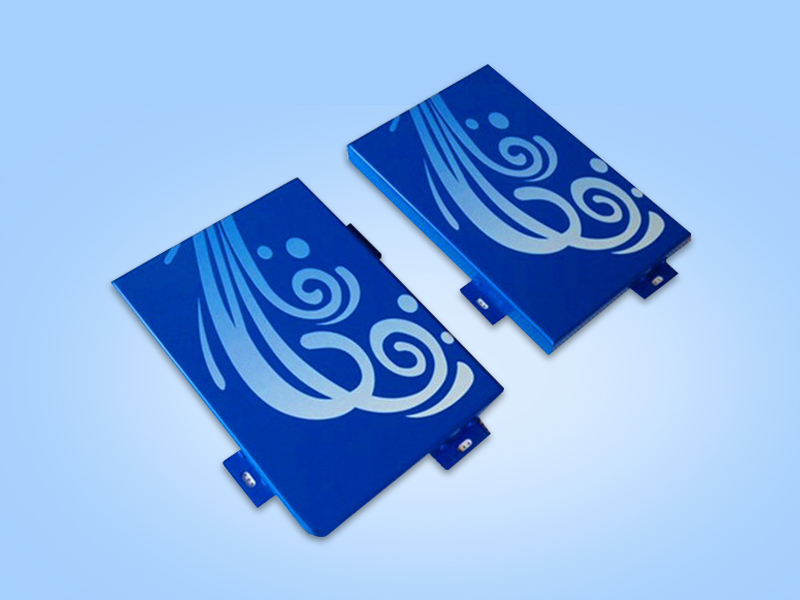

In the construction industry,Aluminum veneerAs a commonly used building material, its seamless splicing technology is an important issue of concern to people. With the increasing demand for building appearance, seamless splicing technology has become one of the important indicators for evaluating the quality of aluminum veneer. Below, we will provide a detailed introduction to the advantages of seamless splicing technology for aluminum veneer.

The seamless splicing technology of aluminum veneer can improve the overall aesthetics of buildings. The oxide film formed on the surface of aluminum veneer after anodizing treatment can effectively isolate the surface of aluminum veneer from the external environment, thereby reducing the influence of oxidizing substances such as air and water vapor on the aluminum veneer. This oxide film can also improve the wear resistance and weather resistance of aluminum veneer, extending its service life. This seamless splicing technology can provide a smoother and more neat appearance for buildings, which is beneficial for improving the overall aesthetics and decorative effect of buildings.

The seamless splicing technology of aluminum veneer can improve the waterproof performance of buildings. The oxide film formed on the surface of aluminum veneer after anodizing treatment can effectively isolate the contact between the aluminum veneer surface and water molecules, thereby reducing the impact of moisture and corrosion on the aluminum veneer. This seamless splicing technology can make the surface of the building smoother, which is beneficial for reducing the residence time of rainwater on the surface of the building, thereby improving the waterproof performance of the building.

Again, seamless splicing technology of aluminum veneer can improve the insulation performance of buildings. The oxide film formed on the surface of aluminum veneer after anodizing treatment can effectively prevent heat transfer, thereby improving the insulation performance of aluminum veneer. This seamless splicing technology can make the surface of the building smoother, which is conducive to reducing the loss of heat on the surface of the building, thereby improving the insulation performance of the building.

Finally, it should be noted that corresponding waterproof, anti-corrosion, and fire prevention measures should be taken when using aluminum veneer. In practical applications, the selection should be based on specific building requirements and budget factors, and aluminum veneer products with good quality and service should be chosen. During the application process, corresponding waterproof measures, anti-corrosion measures, and fire prevention measures should be taken to ensure the safety and health of the building.

The seamless splicing technology of aluminum veneer has some unique characteristics and advantages. It can not only improve the overall aesthetics and decorative effect of buildings, but also enhance their waterproof and insulation performance, which is beneficial for improving the comfort and practicality of buildings. We should closely monitor the latest developments and application cases of aluminum veneer technology, and actively promote the application and development of aluminum veneer in various fields. During the application process, attention should be paid to construction quality and safety issues to avoid potential safety hazards and quality problems.

- previous page:What is the future development of aluminum veneer?

- Next page:Advantages and market prospects of aluminum veneer

Customer service QQ

Customer service QQ