Industry information

Company News

- Curtain wall aluminum veneer: a fashionable new favorite for creating modern architecture

- Aluminum veneer: the 'hidden hero' of modern architecture

- Aluminum veneer: the 'invisible hero' of modern architecture

- Fluorocarbon aluminum veneer: the "fashionista" in the aluminum industry

- The Charm of Aluminum Veneer: A Fashionable Choice for Modern Architecture

Industry dynamics

- Design aesthetics of aluminum veneer exterior wall decoration

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

- Fluorocarbon aluminum veneer: not just aluminum sheet, but also a combination of art and technology

- Aluminum veneer customization, creating personalized spatial aesthetics

- Popular choices for aluminum veneer building decoration

Frequently asked questions

- How is aluminum veneer produced and manufactured?

- What issues should be noted during the processing of aluminum veneer?

- How to apply aluminum veneer in construction and interior decoration?

- What are the applications of aluminum veneer in the interior decoration industry?

- What are the applications of aluminum veneer in the construction industry?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

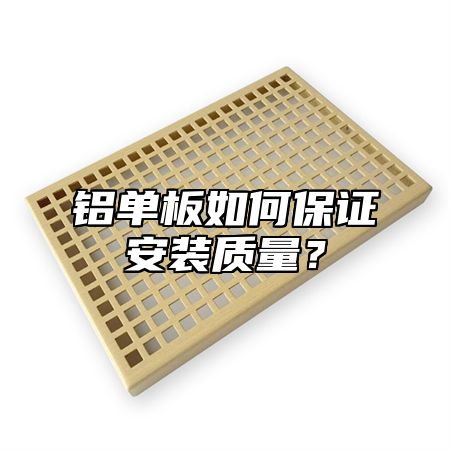

How to ensure the installation quality of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 23, 2025 00:11:41

- Click:0

Aluminum veneerAs a new type of building material, its installation quality is of great significance for the safety, aesthetics, and service life of the project. Below, we will introduce some methods to ensure the installation quality of aluminum veneer.

1. Strict selection and inspection of materials

In the actual material selection process, strict inspection and screening of aluminum veneer materials are required to ensure that product quality meets national standards and customer requirements. Specifically, methods such as spectral analysis, hardness testing, and strength testing can be used to comprehensively detect and evaluate the material of aluminum veneer. You can also choose suitable brands and suppliers based on the actual situation to avoid installation quality issues caused by material problems.

1. Fine measurement and positioning

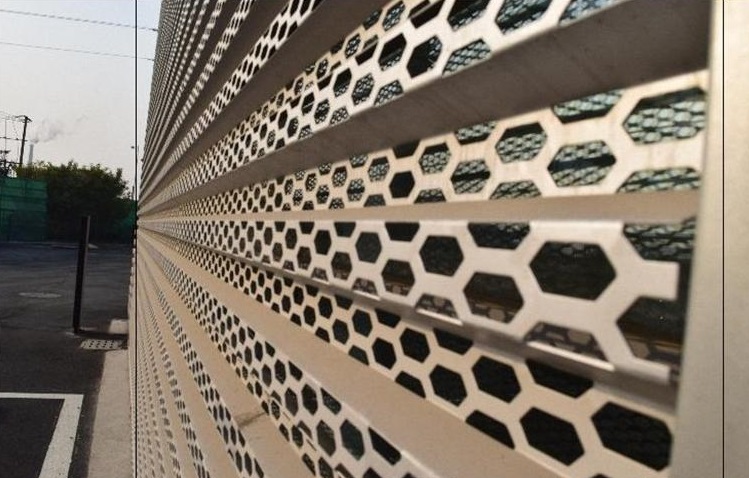

In the actual installation process, it is necessary to finely measure and position the position and angle of the aluminum veneer to ensure that the installation accuracy and flatness of the aluminum veneer meet the design requirements. Specifically, tools such as laser rangefinders and level gauges can be used to accurately measure and locate the position and angle of aluminum veneers; Alternatively, BIM technology, virtual reality technology, and other methods can be used to simulate construction and optimize design, in order to improve installation accuracy and efficiency.

1. Standardize construction processes and operations

Standardizing construction processes and operations is also one of the important means to ensure the quality of aluminum veneer installation. In the actual construction process, it is necessary to follow the prescribed procedures and operating steps to avoid installation quality problems caused by improper operation. For example, a segmented construction approach can be adopted, dividing the entire project into multiple stages for construction, with dedicated managers and coordinators for each stage; Or establish a sound management system and assessment mechanism to evaluate and reward the performance of construction personnel, thereby stimulating their work enthusiasm and creativity.

1. Strengthen quality control and inspection

Strengthening quality control and inspection is also one of the important means to ensure the installation quality of aluminum veneer. In the actual construction process, it is necessary to strictly control and inspect the installation quality of aluminum veneer to ensure that the product quality meets the standards and customer requirements. Specifically, various inspection methods such as visual inspection, physical performance testing, and chemical analysis can be used to comprehensively detect and evaluate the installation quality of aluminum veneer. We can also establish a sound quality management system and feedback mechanism to promptly address any quality issues discovered and ensure construction quality.

Ensuring the installation quality of aluminum veneer is one of the important directions for the development of enterprises. In addition to the methods mentioned above, suitable methods can also be selected for implementation based on the actual situation. Only by continuously optimizing the installation plan can we meet the needs and expectations of customers, improve the competitiveness and market share of the enterprise.

Customer service QQ

Customer service QQ