Industry information

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer curtain wall: the beauty of the integration of architectural aesthetics and technology

- Aluminum veneer: a fashionable outerwear for industrial buildings

- Fluorocarbon aluminum veneer: the fashionable new favorite in the aluminum industry

- Curtain Wall Aluminum Veneer: The Unique Charm of Architectural Aesthetics

Industry dynamics

- Recommended Guide for Choosing Aluminum Veneer

- Can aluminum veneer be applied to the exterior design of office buildings?

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- How has aluminum veneer become the preferred material for modern architecture?

- Aluminum veneer customization, creating an artistic journey of exclusive space

Frequently asked questions

- What are the applications of aluminum veneer in the interior decoration industry?

- What factors will affect the price of aluminum veneer?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the applications of aluminum veneer in the construction industry?

- How to apply aluminum veneer in construction and interior decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Design and Manufacturing Process Analysis of Twisted 2.5mm Aluminum Veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 27, 2025 19:05:38

- Click:0

Twist 2.5mmAluminum veneerIt is a unique building decoration material that makes the shape and appearance of aluminum veneer more diverse and creative through bending and twisting. Below, we will provide a detailed introduction to the design and manufacturing process of twisted 2.5mm aluminum veneer.

1、 Design

1. Styling design: The design of twisted 2.5mm aluminum veneer needs to consider its usage environment and functional requirements, as well as decorative effects and other factors. Designers usually design shapes based on the client's needs and the overall style of the building, including shape, size, color, and other aspects.

2. Structural design: The structural design of twisted 2.5mm aluminum veneer needs to consider factors such as its strength and stability, as well as ease of installation and maintenance. Designers usually use reinforcement or support structures to improve its strength and stability.

2、 Manufacturing process

1. Raw material selection: The manufacturing of twisted 2.5mm aluminum veneer requires the use of high-quality aluminum alloy materials, generally AA1100, 3003, 5050 and other series of aluminum alloy materials.

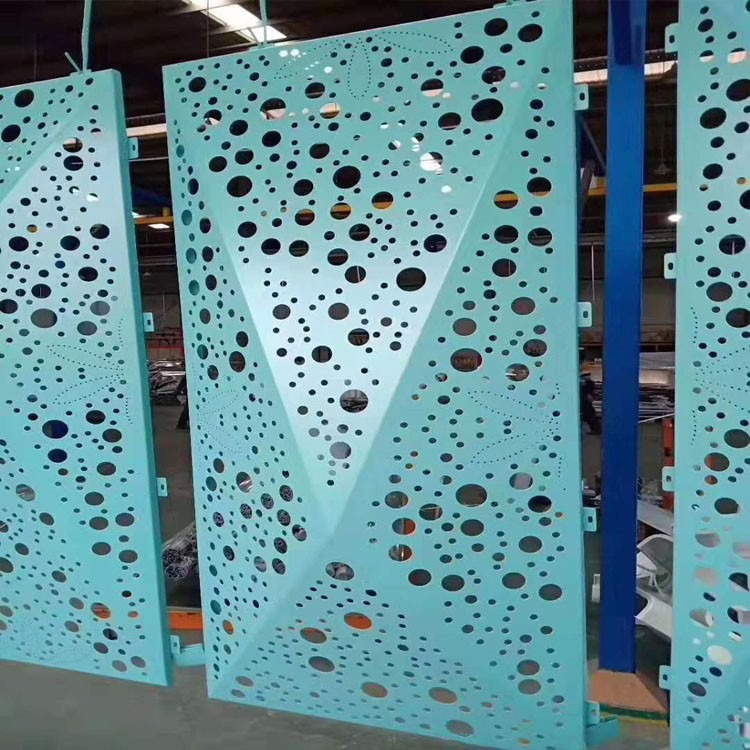

2. Cutting and processing: Cut and process raw materials according to design requirements, generally using CNC cutting machines to ensure dimensional accuracy and surface smoothness.

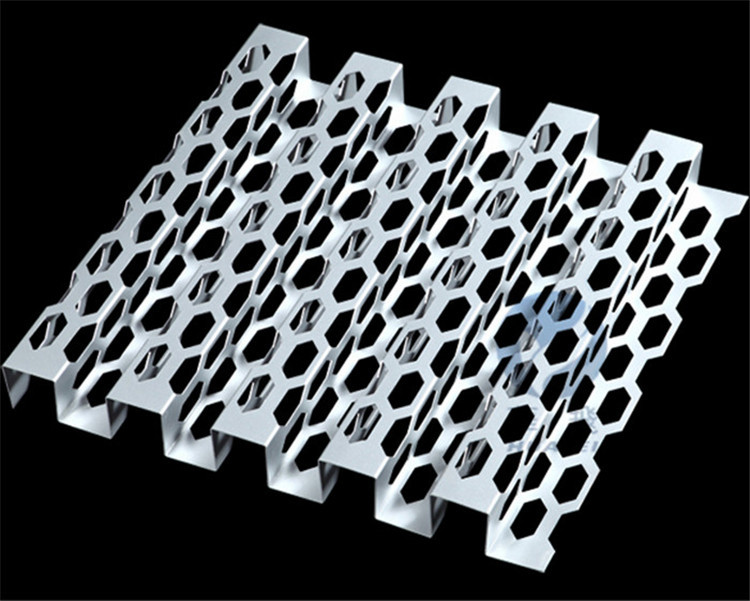

3. Bending Forming: Place the cut aluminum plate on a bending mold and bend it into the desired shape and appearance through heating and pressure.

4. Surface treatment: For twisted 2.5mm aluminum veneer, surface treatment is very important. Surface treatment is usually carried out through methods such as anodizing, spraying, and rolling to improve its corrosion resistance and aesthetics.

3、 Application scope

Twisted 2.5mm aluminum veneer is widely used in commercial buildings, residential buildings, public buildings, and other fields. For example, in commercial buildings, it can be used to make large billboards, display stands, etc; In residential buildings, it can be used to make balcony railings, door and window decorations, etc; In public buildings, it can be used to make curtain walls, ceilings, etc.

4、 Precautions

When manufacturing twisted 2.5mm aluminum veneer, the following issues need to be noted:

1. Ensure that the quality and thickness of raw materials meet the requirements to ensure the quality and strength of the product.

2. During the processing, temperature and pressure should be controlled to avoid deformation or damage to the aluminum plate.

3. During the surface treatment process, attention should be paid to controlling the time and temperature to avoid problems such as color difference or oxidation on the surface.

Twisted 2.5mm aluminum veneer is a building decoration material with unique design and manufacturing process, which can make the shape and appearance of aluminum veneer more diverse and creative through bending and twisting. With the development of technology and people's increasing demands for environmental protection, energy conservation, and other aspects, twisted 2.5mm aluminum veneer will be more widely used and developed.

Customer service QQ

Customer service QQ