Frequently asked questions

Company News

- Aluminum veneer curtain wall: the new darling of modern architecture?

- Aluminum veneer curtain wall: a fashionable outerwear for buildings, an environmentally friendly new choice!

- Aluminum veneer customization, artistic interpretation of personalized space

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- The Charm Journey of Hyperbolic Aluminum Veneer: One Board, One World

Industry dynamics

- Aluminum veneer customization, creating personalized space and new fashion

- What is the pressure resistance performance of curtain wall aluminum veneer?

- Curtain wall aluminum veneer: the new darling of modern architecture and the guardian of low-carbon life!

- Aluminum veneer: understated luxury in modern architecture

- Installation Guide for Aluminum Square Ceiling of Curtain Wall

Frequently asked questions

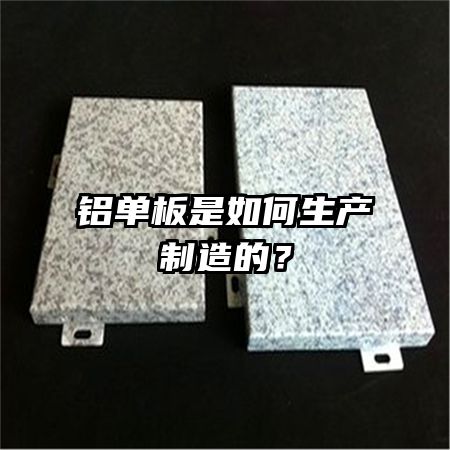

- How is aluminum veneer produced and manufactured?

- How to apply aluminum veneer in construction and interior decoration?

- What are the applications of aluminum veneer in the interior decoration industry?

- What are the types of aluminum veneer?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How is aluminum veneer produced and manufactured?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-24 22:11:10

- Click:0

Aluminum veneerHow is it produced and manufactured?

Abstract: This article will elaborate on the production and manufacturing process of aluminum veneer, including four aspects: material selection, processing and forming, surface treatment, and installation. Through rich content and accurate language, it will introduce the production process of aluminum veneer to readers.

1、 Aluminum material selection

1. Raw material selection: Aluminum veneer usually uses high-purity, lightweight, and corrosion-resistant aluminum alloys as raw materials, commonly including AA1100, AA3003, AA5005, etc.

2. Thickness and size selection: Choose the appropriate thickness and size according to different usage scenarios and requirements. Typically, the thickness of aluminum veneer ranges from 1.5mm to 4.0mm.

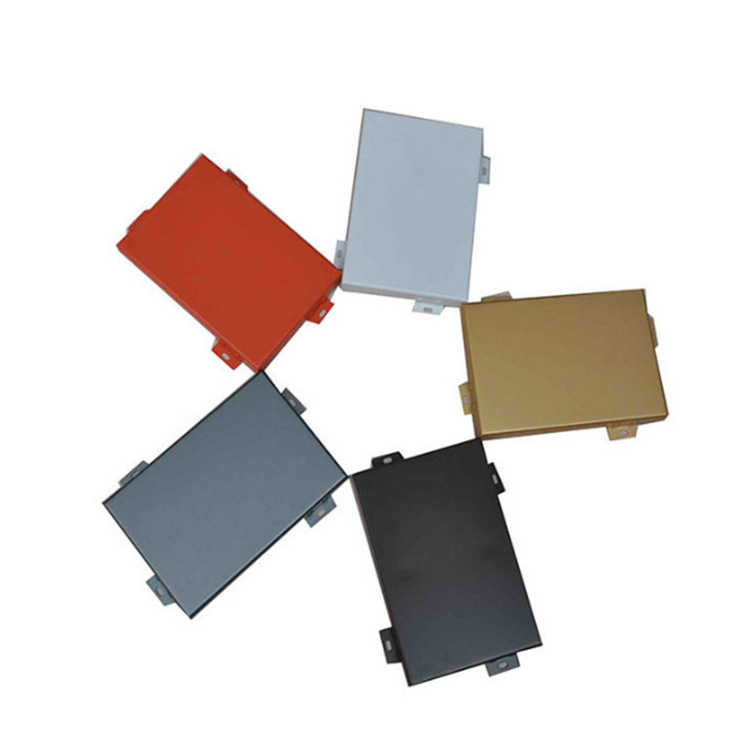

3. Coating selection: Choose the appropriate coating material based on the appearance effect and environmental requirements, commonly including polyester coating, fluorocarbon coating, and alumina coating.

2、 Processing and Forming

1. Cutting and trimming: Cut and trim the raw materials according to the required size to obtain aluminum plates of appropriate size.

2. Bending and bending: Use mechanical equipment to bend and bend aluminum plates in order to produce the desired shape.

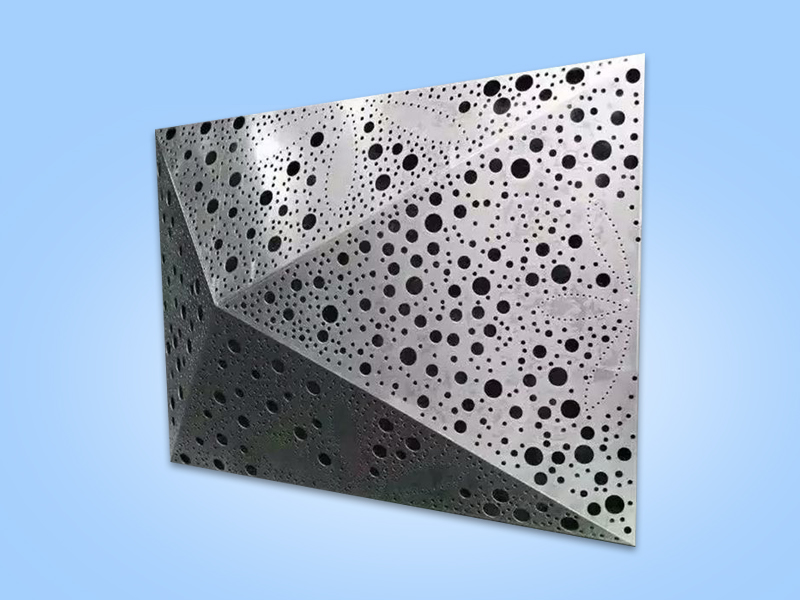

3. Punching and cutting: necessary openings and holes are made for aluminum plates through processes such as punching and cutting.

3、 Surface treatment

1. Oil and rust removal: Surface treatment of aluminum plates to remove impurities, oil stains, and oxides, ensuring surface cleanliness.

2. Chemical treatment: Acid washing and other methods are used for chemical treatment to enhance the adhesion and corrosion resistance of the aluminum plate surface.

3. Coating treatment: Apply the selected coating material evenly on the surface of the aluminum plate to form a protective layer and decorative effect.

4、 Installation

1. Pre installation debugging: Before actual installation, perform pre installation debugging to ensure that the size and shape of the aluminum veneer meet the requirements.

2. Fixed connection: The aluminum veneer is fixed to the bracket or wall using bolts, rivets, or welding to ensure stability and reliability.

3. Final debugging: After installation is completed, perform final debugging to check for defects or issues, and make necessary repairs and adjustments.

5、 Summary

This article provides a detailed introduction to the production and manufacturing process of aluminum veneer, including four aspects: material selection, processing and forming, surface treatment, and installation. By gradually elaborating, readers can understand the production process of aluminum veneer and gain a deeper understanding of its application in the field of architectural decoration.

- Previous Page: None

- Next page:What are the types of aluminum veneer?

Customer service QQ

Customer service QQ