Industry information

Company News

- Aluminum veneer customization, artistic interpretation of personalized space

- Aluminum veneer curtain wall: a perfect combination of architectural aesthetics and practicality

- Hyperbolic aluminum veneer: the artistic new darling of the aluminum industry

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer customization, creating a new trend of personalized space!

Industry dynamics

- Hyperbolic aluminum veneer: a fashionable choice in architectural art

- The fashion transformation of aluminum veneer: not just materials, but also art

- Exploring the application of 1.5mm aluminum veneer in architectural decoration

- Exploring Hyperbolic Aluminum Veneers: The Aesthetic Choice for Future Architecture?

- 2. Unlimited creativity: Application of hyperbolic aluminum veneer in modern architecture 3 New favorite of aluminum plate:

Frequently asked questions

- What are the types of aluminum veneer?

- How is aluminum veneer produced and manufactured?

- What are the applications of aluminum veneer in the construction industry and how can they be improved?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- How to apply aluminum veneer in construction and interior decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

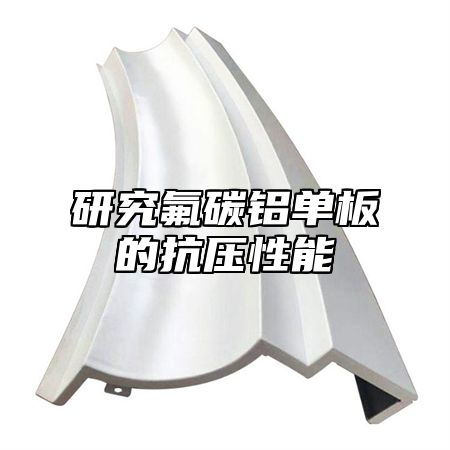

Study on the compressive performance of fluorocarbon aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-12 07:06:36

- Click:0

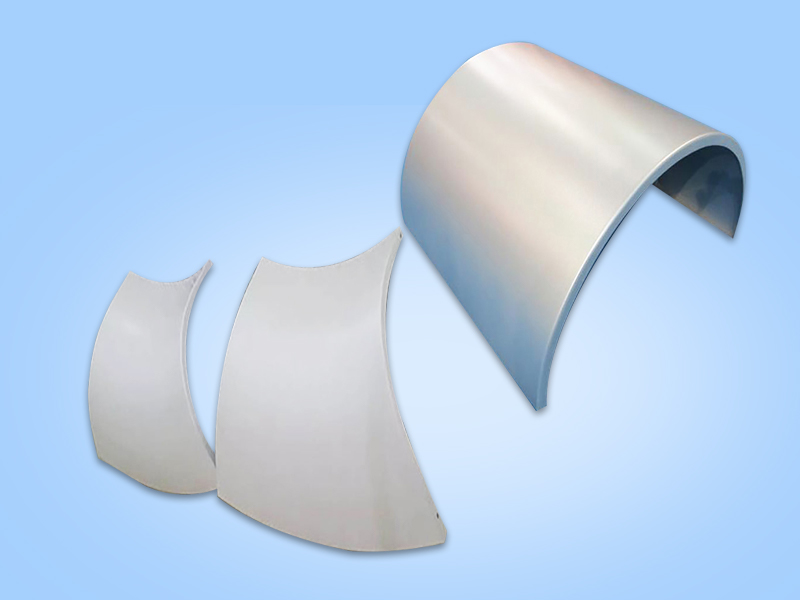

FluorocarbonAluminum veneerAs a new type of building material, its compressive performance is one of its important performance indicators. The compressive performance directly affects the service life and safety of fluorocarbon aluminum veneer. In order to study the compressive performance of fluorocarbon aluminum veneer, a series of experiments and tests are required. The following will provide a detailed introduction to the compressive performance research of fluorocarbon aluminum veneer.

1、 Experimental Design

1. Material preparation: Select fluorocarbon aluminum veneer samples that meet the standards and clean and rust them.

2. Experimental equipment: Compression testing machine is used for the experiment.

3. Experimental method: Place the fluorocarbon aluminum veneer sample in the sample fixture of the compression testing machine, and compress the sample through the compression testing machine until the sample is damaged. Then record the failure mode and failure pressure value of the sample.

2、 Experimental results and analysis

1. Failure modes: Through compression tests on fluorocarbon aluminum veneer samples, it was found that the main failure modes were bending failure and shear failure.

2. Destructive pressure values: Based on experimental results, the destructive pressure values of fluorocarbon aluminum veneer with different specifications and thicknesses can be obtained. Generally speaking, the failure pressure value of fluorocarbon aluminum veneer is related to its thickness and strength. As the thickness and strength increase, the failure pressure value will also increase accordingly.

3. Conclusion: Through experimental research, it can be concluded that the compressive performance of fluorocarbon aluminum veneer is related to its thickness and strength. With the increase of thickness and strength, its compressive performance will also improve accordingly. In practical applications, the appropriate specifications and thickness of fluorocarbon aluminum veneer should be selected according to the specific situation to ensure its service life and safety.

3、 Summary

The above is a detailed introduction to the compressive performance of fluorocarbon aluminum veneer. In practical applications, it is necessary to conduct testing and analysis based on the actual situation to determine the scope of application and usage methods of fluorocarbon aluminum veneer. Attention should also be paid to the quality of materials and construction to ensure the service life and safety of fluorocarbon aluminum veneer.

Customer service QQ

Customer service QQ