Industry information

Company News

- Hyperbolic aluminum veneer: the new darling of future architecture. How much do you know about it?

- Aluminum veneer customization, creating personalized space and new fashion!

- Aluminum veneer customization, creating personalized spatial aesthetics

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Material selection and construction process analysis for customized aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

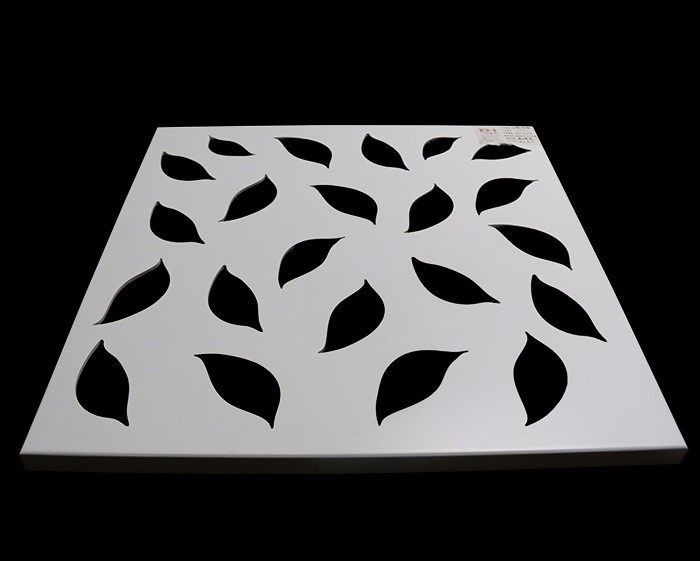

- The Beauty of Creative Design: Decorating and Carving Aluminum Veneers to Create Unique Spaces

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

- What is the availability of aluminum veneer for curtain walls?

Frequently asked questions

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

- What are the applications of aluminum veneer in the construction industry and how can they be improved?

- How is aluminum veneer produced and manufactured?

- What are the applications of aluminum veneer in the construction industry?

- How to apply aluminum veneer in construction and interior decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Construction requirements for imitation wood grain aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 24, 2025 12:51:44

- Click:0

GrainingAluminum veneerAs a building material, its construction requirements are crucial for ensuring the quality and effectiveness of the product. Below is a detailed introduction to the construction requirements of imitation wood grain aluminum veneer.

1、 Material preparation

1. Imitation wood grain aluminum veneer: Select the appropriate imitation wood grain aluminum veneer according to the design drawings and actual needs, and check whether its surface is flat, without obvious defects or color differences.

2. Tools and equipment: including drills, hammers, cutting machines, level gauges, angle rulers, etc. At the same time, it is necessary to prepare corresponding tools such as screwdrivers, wrenches, pliers, etc.

3. Other materials: such as glue, sealant, foam strip, keel, etc.

2、 Construction steps

1. Basic processing

Before construction, it is necessary to treat the base layer, including cleaning debris, filling cracks, polishing smooth, etc. It is also necessary to determine the position and quantity of the keel according to the actual situation and mark it.

2. Install the keel

According to the design drawings and actual situation, use an electric drill or hammer to fix the keel on the wall or ceiling. During the installation process, attention should be paid to the verticality and levelness of the keel to ensure the accuracy and stability of subsequent construction.

3. Install imitation wood grain aluminum veneer

Install the imitation wood grain aluminum veneer according to the requirements of the design drawings. Apply glue to the back of the aluminum veneer and then stick it onto the keel. During the pasting process, attention should be paid to the tightness and flatness between the aluminum veneer and the keel to ensure the beauty and stability of the product.

4. Joint filling and sealing

After installation, it is necessary to fill and seal the joints of the aluminum veneer. Fill the gap at the joint with foam strip, and then seal it with sealant. During the filling and sealing process, attention should be paid to the uniformity and compactness of the material to ensure the waterproof and durability of the product.

3、 Precautions

During the construction process, it is necessary to pay attention to safety issues and avoid accidental injuries. At the same time, attention should be paid to the hygiene and cleanliness of the construction environment to ensure the quality and effectiveness of the product.

When installing imitation wood grain aluminum veneer, attention should be paid to the direction and angle of the aluminum veneer to ensure the correctness and aesthetics of the product.

During the filling and sealing process, attention should be paid to the uniformity and compactness of the materials to ensure the waterproof and durability of the product.

4、 Conclusion

The construction requirements for imitation wood grain aluminum veneer are important measures to ensure product quality and effectiveness. In the future development, with the increasing demand for building materials, imitation wood grain aluminum veneer will be widely used. We will further strengthen the research and application promotion of imitation wood grain aluminum veneer, creating a better and more comfortable living environment and social atmosphere for people.

Customer service QQ

Customer service QQ