Industry information

Company News

- Fluorocarbon aluminum veneer: a new favorite in architecture, with both appearance and performance

- Hyperbolic aluminum veneer: the "fashionable coat" of modern architecture

- Curtain wall aluminum veneer: a new chapter in the "coat" of modern architecture

- Hyperbolic aluminum veneer: an elegant choice for modern architecture

- Fluorocarbon aluminum veneer: a fashionable choice in modern architecture

Industry dynamics

- character

- Aluminum veneer customization, creating personalized spatial aesthetics

- Fluorocarbon aluminum veneer: the new favorite of modern architecture, environmentally friendly and aesthetically pleasing

- Design aesthetics of aluminum veneer exterior wall decoration

- Popular choices for aluminum veneer building decoration

Frequently asked questions

- What are the applications of aluminum veneer in the construction industry and how can they be improved?

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the applications of aluminum veneer in the construction industry?

- How is aluminum veneer produced and manufactured?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality Inspection Standards for Aluminum Veneer Manufacturers' Products

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 1, 2025 21:32:20

- Click:0

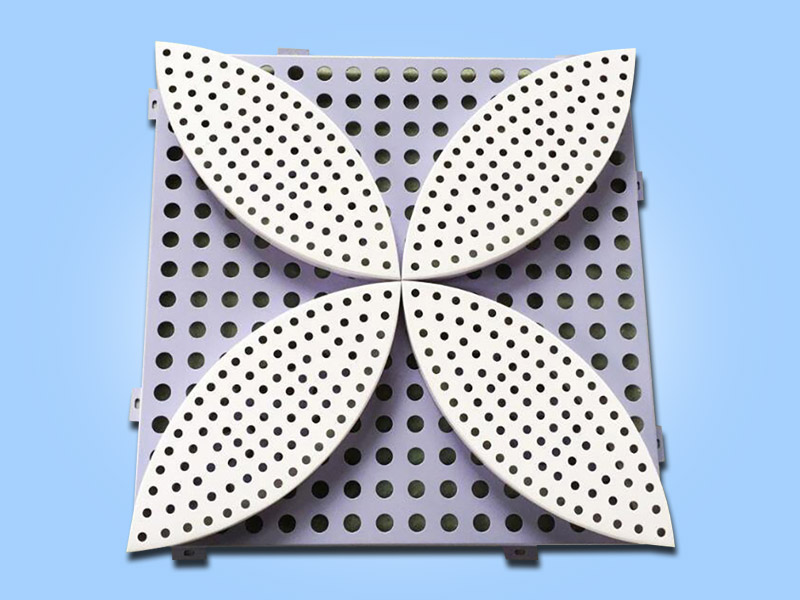

Aluminum veneerAs a building decoration material, product quality testing is one of the important guarantees for enterprises to ensure product quality and customer trust. Below, we will provide a detailed introduction to the quality inspection standards for aluminum veneer manufacturers' products.

1、 Raw material quality control

The quality of raw materials is one of the important factors affecting product quality. Aluminum veneer manufacturers need to pay attention to the quality control of raw materials, select raw material suppliers that meet standards and requirements, conduct strict inspections and tests on raw materials, and ensure the quality and stability of raw materials. The quality control level of raw materials can be improved by establishing raw material procurement records and strengthening supplier management.

2、 Production process control

Production process is one of the important factors affecting product quality. Aluminum veneer manufacturers need to pay attention to the control of production processes, develop reasonable production processes and operating standards, strengthen monitoring and adjustment of the production process, and ensure the quality and stability of products. The level and efficiency of production processes can be improved by strengthening process training and management, introducing advanced production processes and technologies, and other means.

3、 Finished product quality inspection

Finished product quality inspection is one of the important means to ensure product quality. Aluminum veneer manufacturers need to establish a comprehensive quality inspection system for finished products, which includes comprehensive testing and inspection of the produced aluminum veneer, including surface flatness, color uniformity, strength, and other indicators. The quality inspection capability and level of finished products can be improved by introducing advanced testing equipment and technology.

4、 Quality control of after-sales service

The quality of after-sales service is one of the important guarantees for enterprises to win customer trust and loyalty. Aluminum veneer manufacturers need to focus on controlling the quality of after-sales service, providing high-quality pre-sales consultation, installation guidance, maintenance, complaint handling and other services to meet customer service needs and requirements. The quality and efficiency of after-sales service can be improved by strengthening employee training and management, introducing advanced technology and equipment, and other means.

5、 Quality Management System Certification

Quality management system certification is one of the important means for enterprises to improve their quality management level and competitiveness. Aluminum veneer manufacturers need to pay attention to the construction of quality management systems, pass international standards such as ISO9001 certification, establish a sound quality management system and process, and improve the quality management level and competitiveness of the enterprise. The certification and continuous improvement of the quality management system can be achieved through strengthening internal management and external audits.

The product quality inspection standards of aluminum veneer manufacturers need to focus on multiple aspects such as raw material quality control, production process control, finished product quality inspection, after-sales service quality control, and quality management system certification. Aluminum veneer manufacturers need to develop reasonable product quality testing standards and plans based on their own situation and market demand, continuously improving the quality and service level of their products. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and contribute to the development of society.

Customer service QQ

Customer service QQ