Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Hyperbolic aluminum veneer: the new darling of architectural aesthetics

- Hyperbolic aluminum veneer: the new darling of future architecture. How much do you know about it?

- Curtain wall aluminum veneer: a fashionable choice for modern architecture

Industry dynamics

- Customized aluminum veneer makes buildings more in line with people's aesthetic trends

- Hyperbolic aluminum veneer: creating the beauty of future architecture

- The development trend and market prospects of aluminum veneer for exterior walls and curtain walls

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

Frequently asked questions

- How is aluminum veneer produced and manufactured?

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

- What are the applications of aluminum veneer in the interior decoration industry?

- What factors will affect the price of aluminum veneer?

- What are the applications of aluminum veneer in the construction industry?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Unveiling the production process of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-25 20:46:34

- Click:0

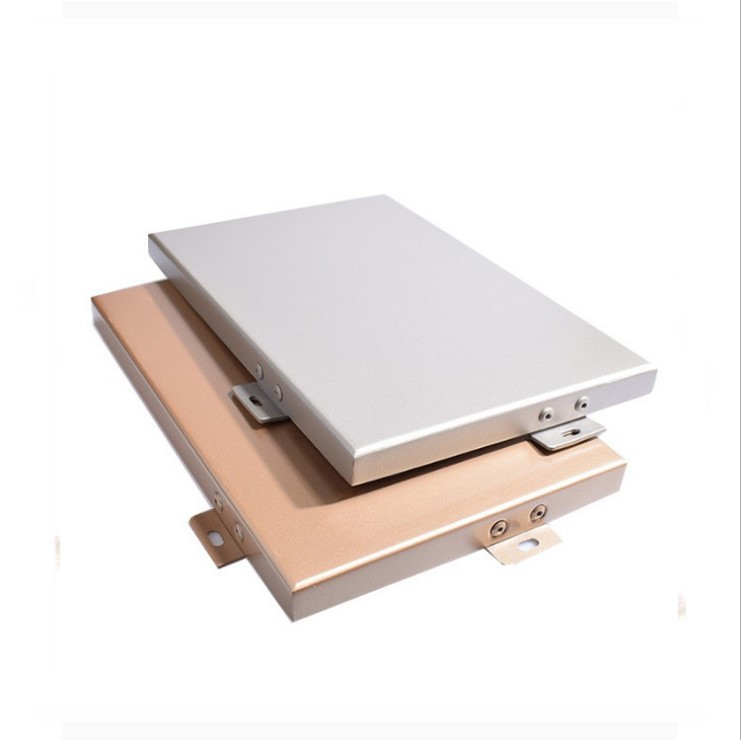

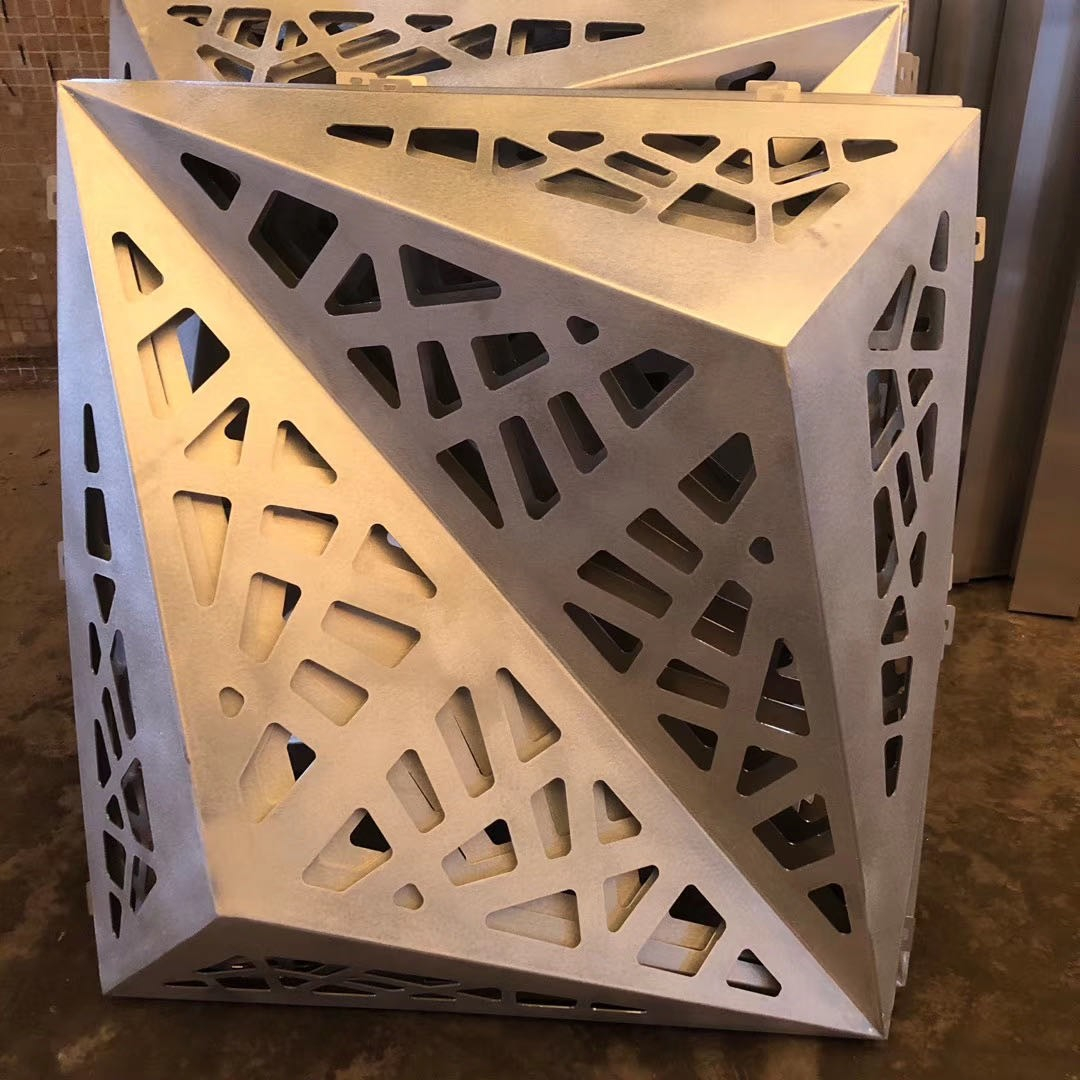

Aluminum veneerAs a new type of building material, it has many advantages and characteristics. Its production process is also very complex and refined. Below, we will reveal the production process of aluminum veneer.

1、 Raw material preparation

The main raw materials for aluminum veneer are aluminum plates and surface treatment materials. Aluminum plates are usually made of series such as 1100, 3003, 5052 aluminum alloy plates, and surface treatment materials include anodized film, spray film, roller press film, etc. Strict inspection and screening of raw materials are required before production to ensure that the quality meets the requirements.

2、 Cutting materials

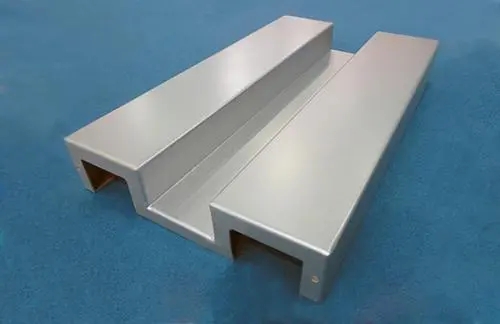

Cut and cut the aluminum sheet according to the design requirements to obtain the desired size and shape of the aluminum veneer. This process requires the use of professional cutting equipment and techniques to ensure cutting accuracy and dimensional precision.

3、 Sheet metal processing

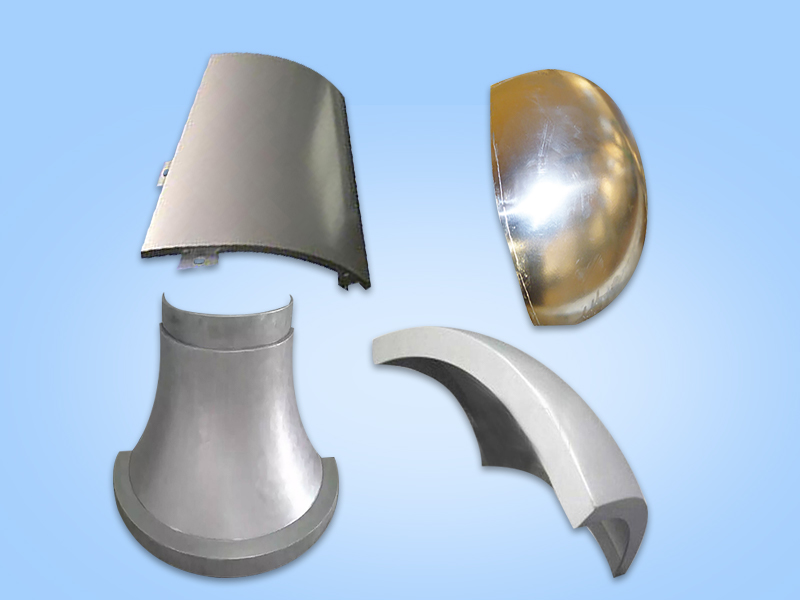

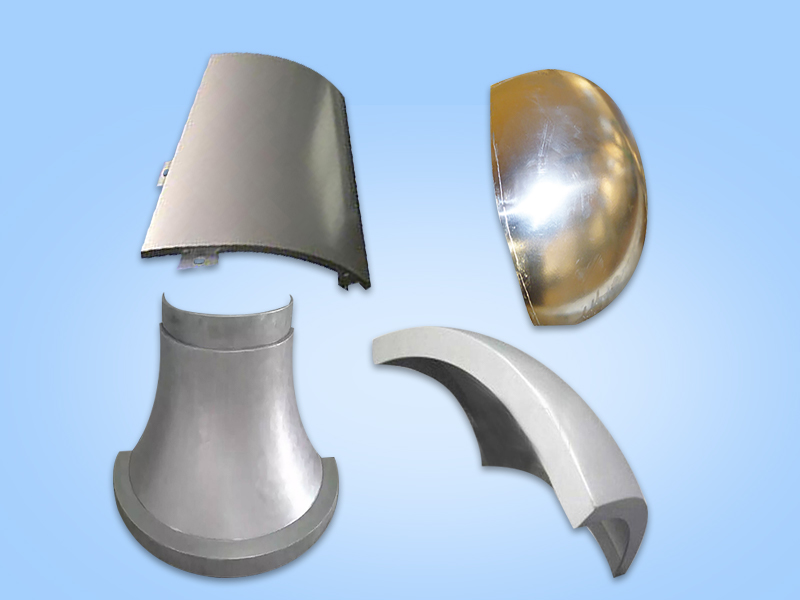

Perform sheet metal processing on the aluminum plate after cutting, including bending, punching, welding, and other processes. This process requires the use of professional sheet metal equipment and technology to ensure that the machining accuracy and quality meet the requirements.

4、 Surface treatment

The surface treatment of aluminum veneer is a crucial step that can affect its appearance and performance. Common surface treatment methods include anodizing, spraying, rolling, etc. These methods require the use of professional equipment and techniques to ensure that the quality and effectiveness of surface treatment meet the requirements.

5、 Install accessories

The installation of aluminum veneer requires the use of various accessories, such as keel systems, sealing strips, corner brackets, etc. These accessories need to be selected and installed according to design requirements to ensure installation accuracy and stability.

6、 Inspection and packaging

After production is completed, strict inspection and testing of aluminum veneer are required to ensure product quality meets standards and requirements. Qualified aluminum veneer needs to be packaged and transported to ensure that the product is not damaged or contaminated.

7、 Summary

The production process of aluminum veneer includes raw material preparation, cutting, sheet metal processing, surface treatment, installation of accessories, inspection, and packaging. These processes require the use of professional equipment and technology to ensure that the quality and efficiency of production meet the requirements. In the future, with the continuous advancement of technology and the development of society, the production technology of aluminum veneer will continue to develop and improve.

Customer service QQ

Customer service QQ