Industry information

Company News

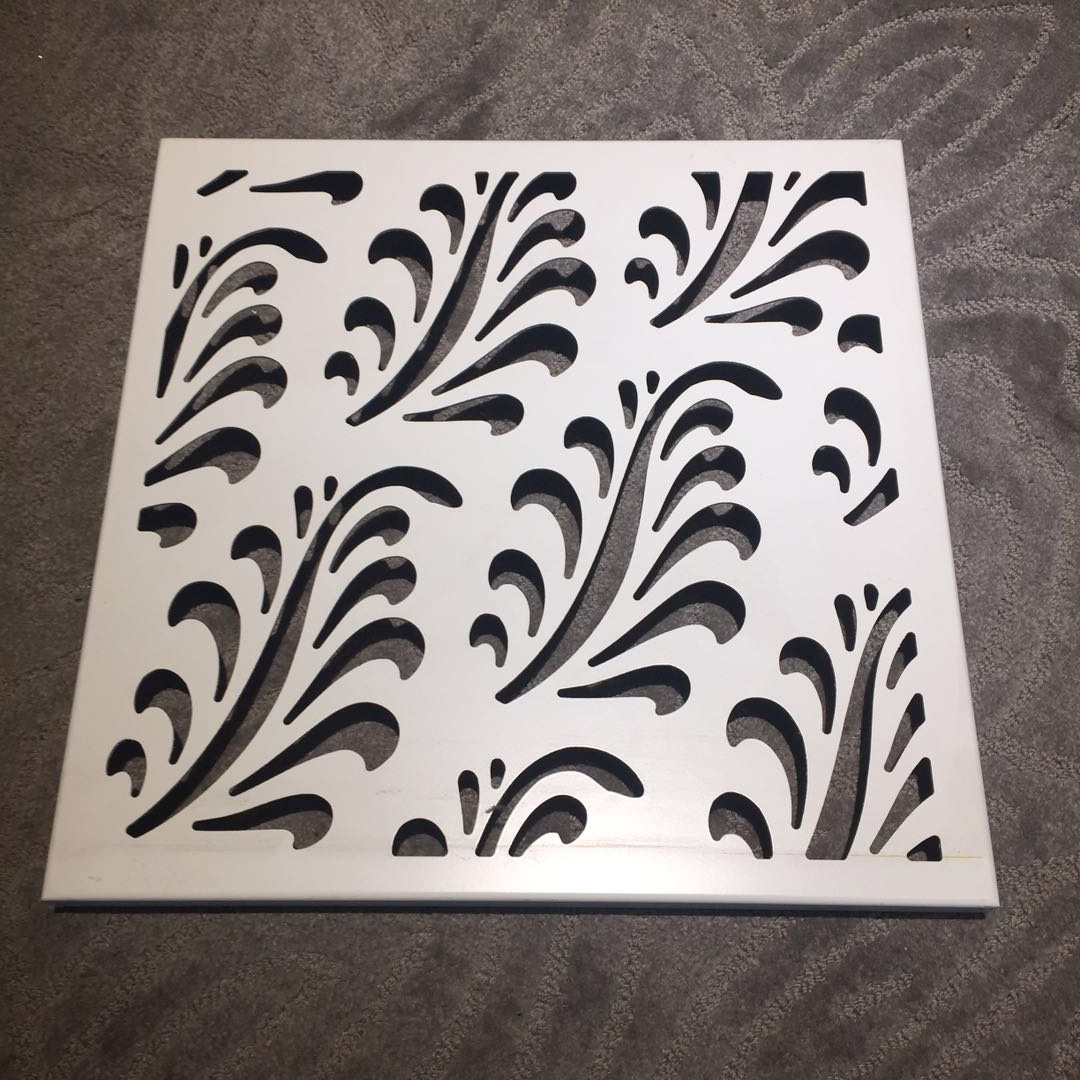

- The fashion charm of hyperbolic aluminum veneer: it's not just about its appearance

- Unveil! The modern magic charm of curtain wall aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall, the new darling of modern architecture?

- Aluminum veneer curtain wall: the fashionable coat of architecture

Industry dynamics

- The secret to cleaning aluminum veneer makes it look brand new

- Aluminum veneer customization, creating personalized space and new fashion

- Lightweight choice, hyperbolic aluminum veneer, creating a new trend of modern home decor!

- Aluminum veneer curtain wall, the "skin" art of modern architecture

- Curtain wall aluminum veneer: the secret weapon of architectural aesthetics

Frequently asked questions

- What issues should be noted during the processing of aluminum veneer?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the types of aluminum veneer?

- How to apply aluminum veneer in construction and interior decoration?

- How is aluminum veneer produced and manufactured?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to ensure the processing quality of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-01 04:14:15

- Click:0

Aluminum veneerAs a lightweight and high-strength building material, it is widely used in exterior wall decoration, roofs, facades and other parts of buildings. To ensure the processing quality of aluminum veneer, it is necessary to start from multiple aspects, including the selection of raw materials, optimization of processing equipment, and control of processing technology. This article will provide a detailed introduction on how to ensure the processing quality of aluminum veneer.

1、 Selection of raw materials

The quality of aluminum veneer is closely related to the quality of its raw materials. When purchasing raw materials, it is necessary to choose high-quality aluminum alloy materials to ensure the strength and hardness of the aluminum veneer. Strict inspection and screening of raw materials are also required to remove impurities and defects, in order to ensure the surface smoothness and flatness of aluminum veneer.

2、 Optimization of processing equipment

Processing equipment is one of the important factors in ensuring the quality of aluminum veneer processing. In order to improve processing efficiency and accuracy, advanced CNC machining equipment and robotic arms are needed to achieve automated production and precise control. Regular maintenance and upkeep of processing equipment are also necessary to ensure its normal operation and stability.

3、 Control of processing technology

The processing technology of aluminum veneer also has a significant impact on its quality. During the processing, it is necessary to strictly control the temperature, humidity, speed and other parameters of each link to avoid deformation or damage caused by environmental factors. It is also necessary to customize the design according to different thicknesses and shapes of aluminum veneers to ensure their processing accuracy and surface quality.

4、 Quality inspection and control

After the completion of aluminum veneer processing, strict quality inspection and control are required. This includes testing and evaluating the dimensions, thickness, surface flatness, color, and other aspects of aluminum veneer. If any problems are found, they need to be adjusted and corrected in a timely manner to ensure that the quality of the aluminum veneer meets the requirements.

5、 After sales service and maintenance

In order to ensure the quality and service life of aluminum veneer during use, it is necessary to provide comprehensive after-sales service and maintenance. This includes regular inspection and maintenance of aluminum veneer, as well as providing professional technical support and solutions. Only in this way can customers use aluminum veneer products with peace of mind.

To ensure the processing quality of aluminum veneer, it is necessary to start from multiple aspects, including the selection of raw materials, optimization of processing equipment, control of processing technology, quality inspection and control, as well as after-sales service and maintenance. Only by doing a good job in these aspects can we provide customers with high-quality aluminum veneer products.

Customer service QQ

Customer service QQ