Industry information

Company News

- Unveiling the Secrets Behind the Beauty of Architecture: Aluminum Veneers for Curtain Walls

- Fluorocarbon aluminum veneer: the "invisible warrior" of modern architecture

- Exploring Hyperbolic Aluminum Veneer: The Fashion Choice for Future Architecture?

- How much do you know about aluminum veneer: a fashionable choice for modern architecture?

- Exploring the unique charm of fluorocarbon aluminum veneer

Industry dynamics

- What are the advantages of fluorocarbon sprayed aluminum veneer compared to aluminum veneer made with traditional coatings?

- Aluminum veneer, the fashionable outerwear of architecture, your new home choice?

- Aluminum veneer: the fashionable choice for modern architecture

- Aluminum veneer curtain wall, the magnificent coat of modern architecture

- Aluminum veneer: not only for exterior walls, but also as a witness to fashion

Frequently asked questions

- How is aluminum veneer produced and manufactured?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

- What are the types of aluminum veneer?

- What are the applications of aluminum veneer in the interior decoration industry?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to choose the most suitable aluminum veneer material?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 2, 2025 15:52:42

- Click:0

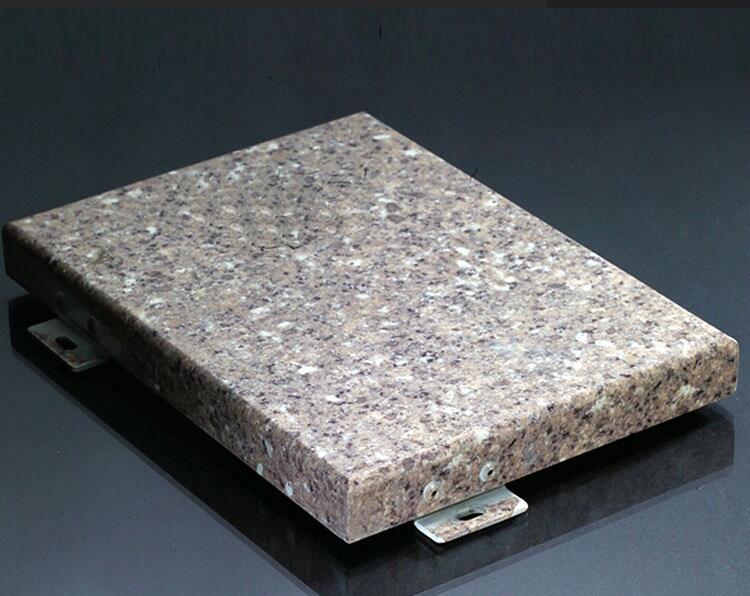

Aluminum veneerIt is a common building material with advantages such as lightweight, corrosion resistance, and easy processing. When selecting aluminum veneer materials, comprehensive consideration should be given to the specific usage environment and requirements. Below, we will provide a detailed introduction on how to choose the most suitable aluminum veneer material.

1、 Material selection

The material of aluminum veneer is one of the important factors affecting its performance and quality. Generally speaking, the material of aluminum veneer is divided into several types such as 1060, 3003, 5052, etc. 1060 aluminum alloy has good corrosion resistance and plasticity, suitable for outdoor construction and decoration; 3003 aluminum alloy has high strength and corrosion resistance, suitable for some special occasions; 5052 aluminum alloy has high strength and corrosion resistance, and is suitable for some important building structures.

2、 Selection of surface treatment

The surface treatment of aluminum veneer is also one of the important factors affecting its performance and quality. Common surface treatment methods include spraying, rolling, anodizing, etc. Spraying treatment can improve the corrosion resistance and appearance quality of aluminum veneer, but attention should be paid to environmental issues; Rolling treatment can improve the wear resistance and corrosion resistance of aluminum veneer, but it requires an increase in production costs; Anodizing treatment can improve the corrosion resistance and hardness of aluminum veneer, but it requires a longer production cycle and higher technical requirements.

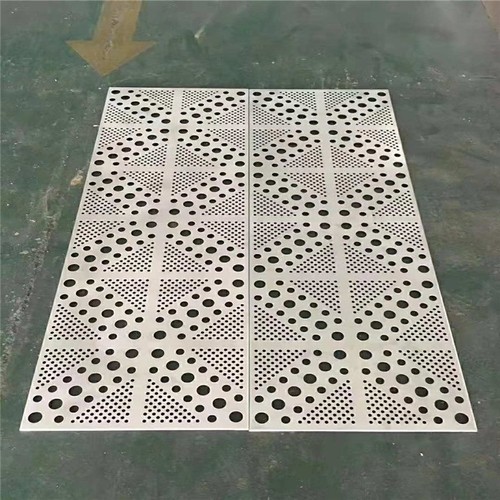

3、 Selection of size and shape

The size and shape of aluminum veneer are also important factors affecting its application effect. When choosing size and shape, it is necessary to consider comprehensively based on the actual usage environment and requirements. Generally speaking, the size and shape of aluminum veneer can be customized according to needs to meet different architectural and decorative requirements. Attention should also be paid to the thickness and strength of aluminum veneer to ensure that it meets safety performance requirements.

4、 Brand and service selection

When choosing aluminum veneer materials, brand and service factors also need to be considered. High quality brands and services can provide better product quality and after-sales service, bringing users a better user experience and economic benefits. When selecting aluminum veneer materials, it is necessary to choose well-known brands and reputable suppliers, and pay attention to understanding and comparing their service levels and after-sales support.

Choosing the most suitable aluminum veneer material requires comprehensive consideration of multiple factors, including material, surface treatment, size and shape, brand service, etc. In practical applications, we need to comprehensively consider specific needs and requirements, and choose the most suitable aluminum veneer material to achieve the best use effect and economic benefits.

Customer service QQ

Customer service QQ