Corporate News

Company News

- Fluorocarbon aluminum veneer, the secret weapon for creating fashionable buildings!

- Curtain Wall Aluminum Veneer: The Beauty of Architecture, See the True Chapter for Details

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- Aluminum veneer customization, creating personalized spatial aesthetics

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Hyperbolic aluminum veneer: a perfect fusion of fashion and technology

- Aluminum veneer curtain wall: an innovative work of architectural art

- Cross disciplinary application of customized aluminum veneer: Beyond tradition, unlocking infinite possibilities

- Personalized customization, aluminum veneer rejuvenates the beauty of the home

- What are the common applications of aluminum veneer in the construction field?

Frequently asked questions

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

- What are the applications of aluminum veneer in the construction industry?

- How is aluminum veneer produced and manufactured?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the types of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The importance of quality identification and quality control of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 26, 2025 14:51:35

- Click:0

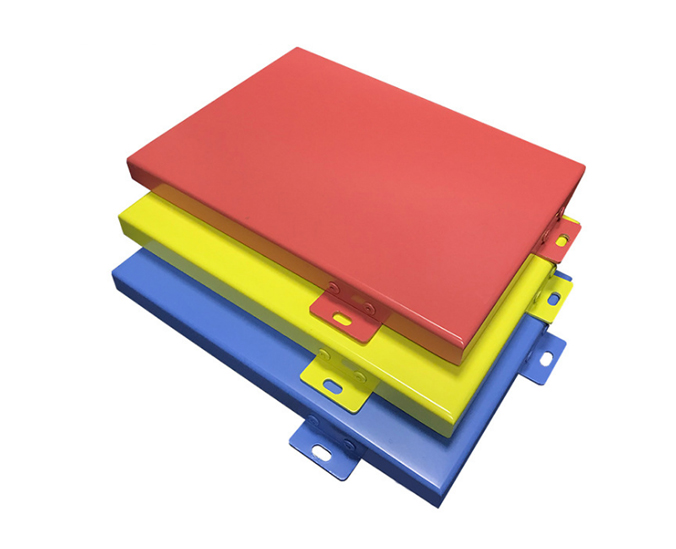

Abstract: Aluminum veneer, as a commonly used building decoration material, has been widely used in recent years. However, due to the existence of various products with uneven quality in the market, quality identification and control of aluminum veneer have become particularly important. This article will elaborate on the importance of quality identification and quality control of aluminum veneer from four aspects.

1、 Raw material selection

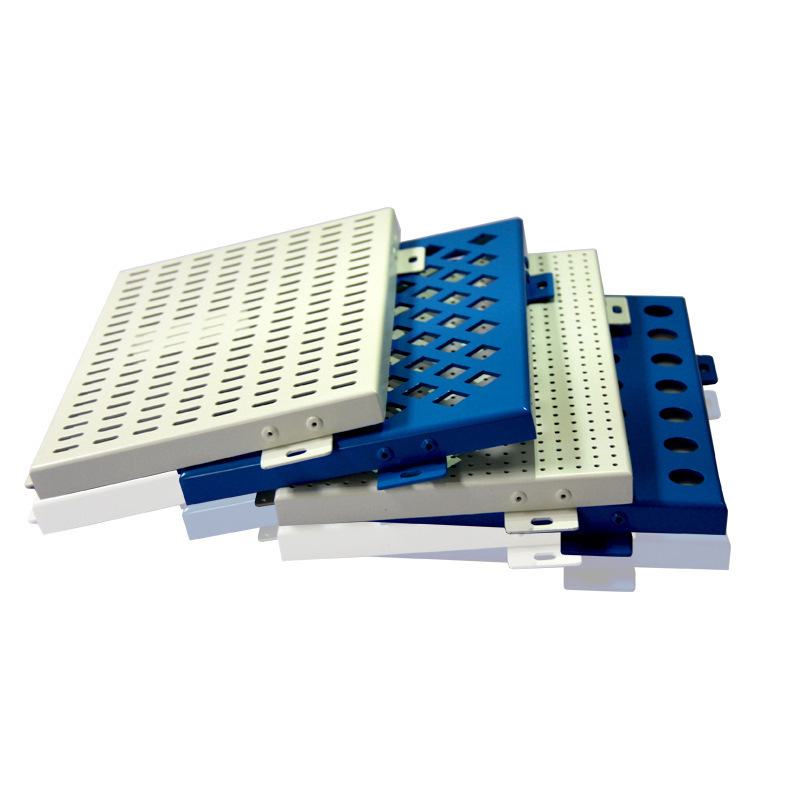

1. Qualified aluminum alloy materials: The quality of aluminum veneer directly affects its service life and performance stability. Therefore, selecting qualified aluminum alloy materials is the primary condition for ensuring the quality of aluminum veneer. Through strict raw material procurement and inspection processes, the use of defective materials can be avoided, ensuring the quality of aluminum veneer.

2. Process control: In the production process of aluminum veneer, process control is also crucial. Accurate cutting, bending, and welding processes can ensure that the size and shape of aluminum veneer meet design requirements, thereby improving product quality.

3. Coating technology: The coating of aluminum veneer is an important step in protecting its surface, increasing its weather resistance, and decorative effect. Reasonable coating technology can ensure that the coating is uniform, firm, and not easily peeled off, thereby improving the service life and quality of aluminum veneer.

2、 Quality Inspection and Control

1. Physical performance testing: By testing the physical properties of aluminum veneer, including tensile strength, yield strength, hardness, and other indicators, the strength and stability of the product can be understood, thereby achieving quality control and optimization.

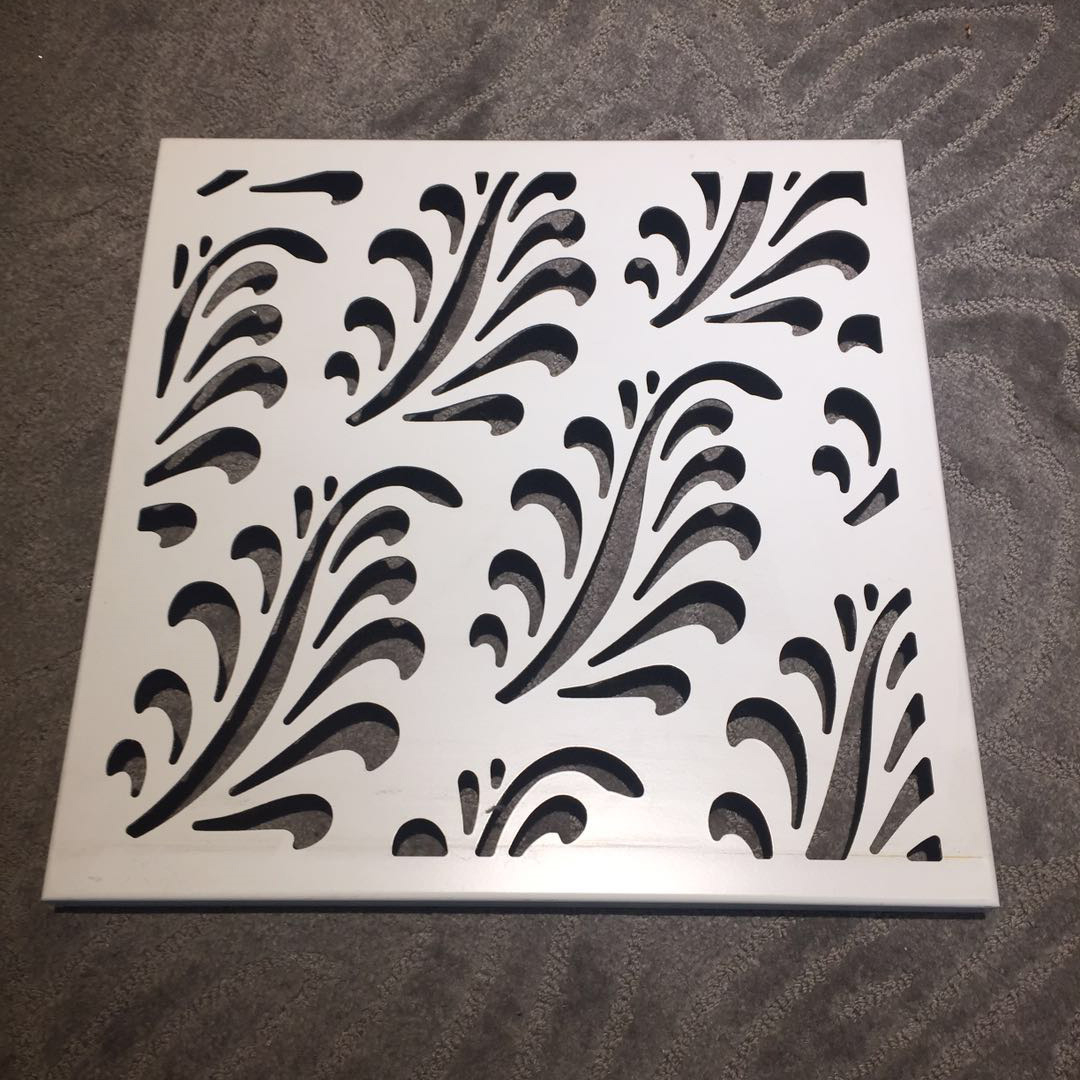

2. Appearance quality inspection: The appearance quality of aluminum veneer is directly related to its decorative effect and aesthetic appearance. By testing surface quality, color, thickness, and other aspects, the consistency and quality of the product can be ensured.

3. Weather resistance test: Aluminum veneer is often used in outdoor environments and needs to have good weather resistance. By simulating natural environmental conditions and testing the weather resistance of aluminum veneer, its service life and performance stability can be evaluated.

3、 Establishment of Quality Management System

1. Strict production control: Establish a sound quality management system to control the entire production process from raw material procurement to finished product delivery. Ensure product stability and consistency through reasonable process flow and strict quality monitoring.

2. Full participation in quality management: Quality control is not just about the production process, but also requires every participant to actively engage in it. Establish an effective training mechanism to enhance employees' quality awareness and skill level, and jointly promote the continuous improvement of aluminum veneer quality.

3. Continuous improvement and feedback: Establish a quality issue feedback mechanism, promptly handle customer complaints and opinions, and improve and optimize based on feedback results to continuously enhance product quality and competitiveness.

4、 Summary of Importance

The quality identification and quality control of aluminum veneer are of great significance for ensuring the performance stability, service life, and decorative effect of the product. By selecting qualified raw materials, strengthening quality inspection and control, and establishing a sound quality management system, the overall quality level of aluminum veneer can be improved, meeting customer needs, and promoting the healthy development of the industry.

5、 Summary

The article elaborates on the importance of aluminum veneer quality identification and quality control from four aspects: raw material selection, quality inspection and control, and establishment of quality management system. Only through reasonable quality control measures and a scientific quality management system can we ensure the stable and consistent quality of aluminum veneer, meet market demand, and promote the sustainable development of the industry.

Customer service QQ

Customer service QQ