Corporate News

Company News

- Fluorocarbon aluminum veneer: the new darling of the construction industry, revealing its charm!

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the fashionable new favorite of modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer customization, creating exclusive space aesthetics

- Hyperbolic aluminum veneer: the secret of artistic innovation in the construction industry!

- Aluminum veneer curtain wall: a perfect interpretation of architectural aesthetics

- Unveiling the production process of aluminum veneer

- Aluminum veneer charm: lightweight building materials, shaping fashionable spaces

Frequently asked questions

- What are the applications of aluminum veneer in the construction industry and how can they be improved?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What issues should be noted during the processing of aluminum veneer?

- What factors will affect the price of aluminum veneer?

- What are the types of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality inspection and control methods for aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 25, 2025 13:39:19

- Click:0

Aluminum veneerQuality inspection and control methods

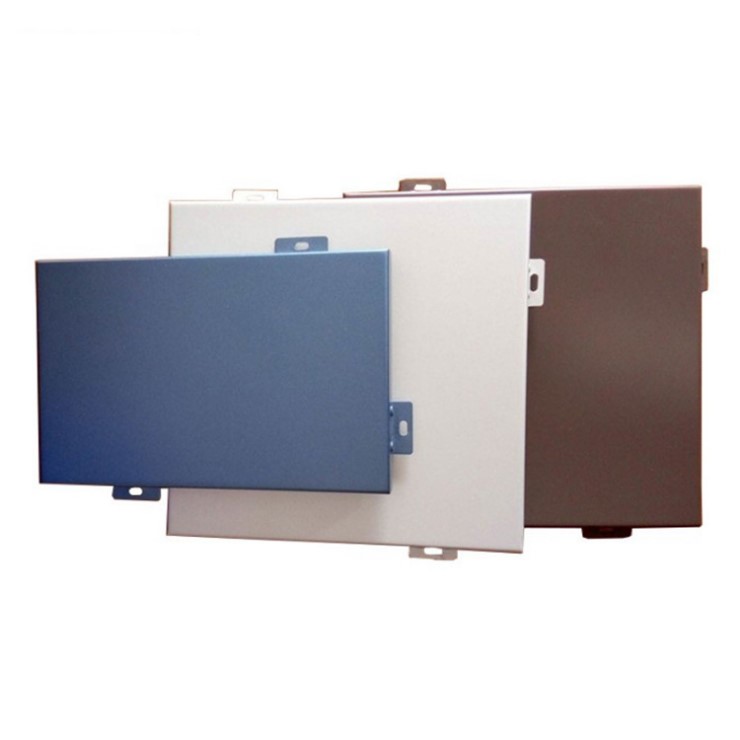

With the continuous development of the construction engineering field, aluminum veneer has been widely used as a high-quality building material. However, quality inspection and control of aluminum veneer are still important links in achieving high-quality construction. This article will elaborate on the quality inspection and control methods of aluminum veneer from the following four aspects.

1、 Raw material testing

1. The purpose of raw material testing

The quality of aluminum veneer is directly affected by the quality of raw materials, so raw material testing is the first step to ensure the quality of aluminum veneer.

2. Testing method

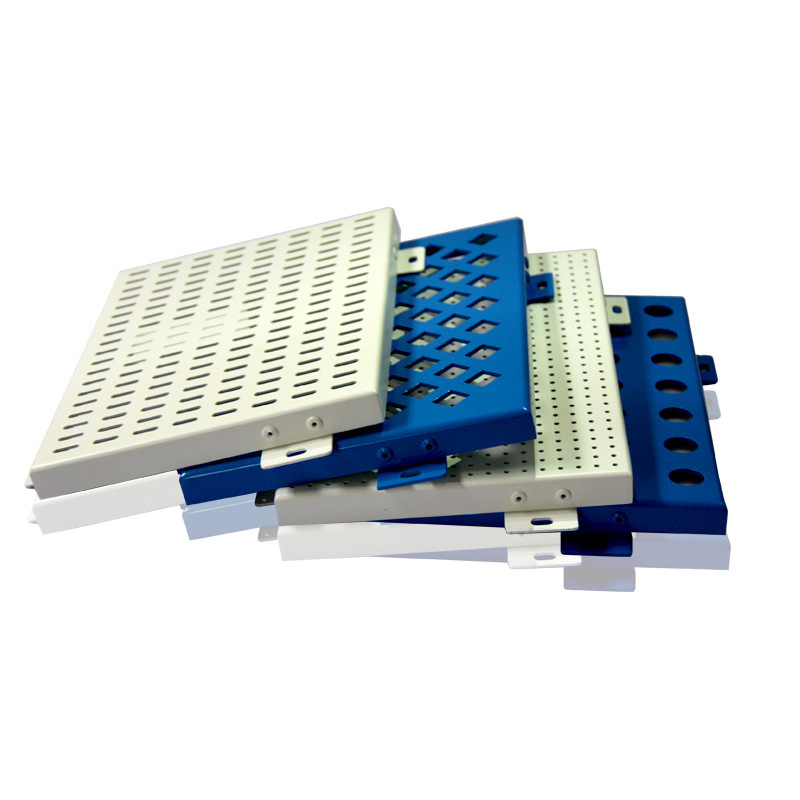

The main method of raw material testing is sampling testing, including aluminum plate testing, aluminum core plate testing, coating testing, etc. Among them, aluminum plate testing mainly focuses on indicators such as flatness and thickness, aluminum core plate testing mainly focuses on its rigidity and quality, and coating testing mainly focuses on coating thickness, hardness, wear resistance, etc.

3. Testing standards

The testing standards for raw materials mainly include national standards and industry standards. In specific operations, appropriate testing indicators need to be set according to the actual needs of the construction project.

2、 Processing technology control

1. The purpose of processing technology control

The processing technology of aluminum veneer will directly affect its quality, so strict control during the processing can avoid some problems that may occur during processing and ensure product quality.

2. Control method

The control of processing technology mainly includes cutting, bending, surface treatment and other processes. During the cutting process, it is necessary to choose appropriate cutting tools and methods; During the bending process, it is necessary to strictly control the bending angle and groove depth; In surface treatment, it is necessary to choose the appropriate treatment method based on the actual situation of the aluminum veneer.

3. Control standards

The control standards for processing technology mainly include process parameters, processing accuracy, processing quality, etc., which need to be reasonably set according to the actual situation of aluminum veneer.

3、 Finished product testing

1. The purpose of finished product testing

Finished product inspection is the final checkpoint for the quality of aluminum veneer, which can detect quality problems and handle them in a timely manner.

2. Testing method

Finished product inspection mainly includes appearance inspection, size inspection, performance inspection, and other aspects. Among them, appearance inspection mainly focuses on the surface performance of aluminum veneer; Size inspection mainly focuses on the size and flatness of aluminum veneer; Performance testing mainly focuses on indicators such as strength, corrosion resistance, and weather resistance of aluminum veneer.

3. Testing standards

Finished product testing needs to follow national and industry standards, and appropriate testing indicators should be set according to the specific needs of the construction project.

4、 Quality Management

1. The purpose of quality management

Quality management is an important means to ensure the quality of aluminum veneer, which can timely detect and correct problems, and promote comprehensive quality management.

2. Management methods

Quality management mainly includes planning, execution, monitoring, evaluation and other aspects. Among them, when formulating the plan, it is necessary to consider the specific situation of each link, clarify quality objectives and tasks; During the execution phase, it is necessary to operate according to the plan and promptly record relevant data; Real time monitoring of the quality of aluminum veneer is required during the monitoring phase to detect problems in a timely manner; The evaluation phase requires a comprehensive evaluation of quality management work and implementation of improvement measures.

3. Management standards

Quality management needs to follow national and industry standards, and set appropriate management indicators according to specific construction project needs.

Summary:

By elaborating on the quality inspection and control methods of aluminum veneer from four aspects: raw material testing, processing technology control, finished product testing, and quality management, it can be seen that in the production process of aluminum veneer, it is necessary to grasp the quality control nodes and ensure the product quality of aluminum veneer.

Customer service QQ

Customer service QQ