Corporate News

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer curtain wall: the fashionable choice for modern architecture?

- Aluminum veneer new fashion: the "silver decoration" revolution of modern architecture

- Fluorocarbon aluminum veneer: the "fashionista" in the aluminum industry

- Hyperbolic aluminum veneer: an artistic trend in the aluminum industry

Industry dynamics

- Hyperbolic aluminum veneer: a new trend in aluminum materials and a beautiful new favorite for home decor

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer: the fashionable new favorite of modern architecture

- What are the advantages of aluminum veneer compared to other exterior wall materials?

- Light luxury fluorocarbon ceiling aluminum veneer installation guide

Frequently asked questions

- How is aluminum veneer produced and manufactured?

- What are the advantages and disadvantages of aluminum veneer compared to other metal materials?

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

- How to apply aluminum veneer in construction and interior decoration?

- What factors will affect the price of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

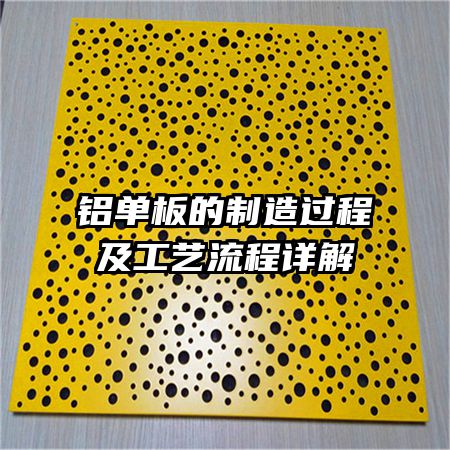

Detailed explanation of the manufacturing process and process flow of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-26 07:54:51

- Click:0

Aluminum veneerDetailed explanation of the manufacturing process and technological flow

Abstract: This article provides a detailed introduction to the manufacturing process and technological flow of aluminum veneer, including four aspects: raw material preparation, processing and forming, surface treatment, and installation.

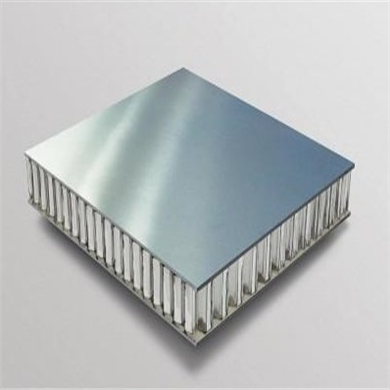

1、 Raw material preparation

1. The selection of aluminum alloy: Firstly, it is necessary to choose suitable aluminum alloy materials, such as aluminum alloys 3003 and 5052. These aluminum alloys have excellent strength and corrosion resistance.

2. Plate cutting: According to design requirements, cut aluminum alloy plates into the required size for subsequent processing and forming.

3. Preparation of auxiliary materials: In addition to aluminum alloy sheets, other auxiliary materials such as glue, sealing strips, etc. need to be prepared to ensure the quality and effectiveness of the aluminum veneer.

2、 Processing and Forming

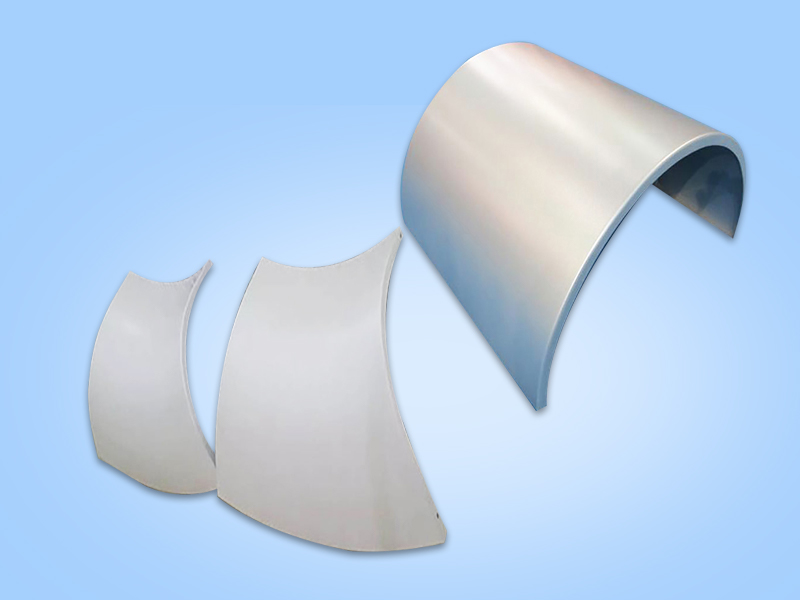

1. Finished drawing design: Based on the aluminum veneer design drawings provided by the architect, detailed labeling and planning are carried out to determine the size and shape of each component.

2. CNC cutting: Using CNC cutting machines to accurately cut aluminum alloy sheets to meet different shape and size requirements.

3. Bending forming: The cut aluminum plate is bent into shape, and through heating and mechanical operation, the aluminum veneer is made to present the desired surface and shape.

3、 Surface treatment

1. Oil removal and purification: After the aluminum veneer is formed, it needs to undergo oil removal and purification treatment to remove surface dirt and grease, ensuring the adhesion and weather resistance of the coating.

2. Spray coating: After oil removal and purification, professional coating equipment is used to apply primer and topcoat coatings to aluminum veneer to increase its weather resistance and decorative effect.

3. Drying and curing: The coated aluminum veneer is sent to an oven for drying and curing, allowing the coating to fully dry and firmly bond with the surface of the aluminum alloy board.

4、 Installation

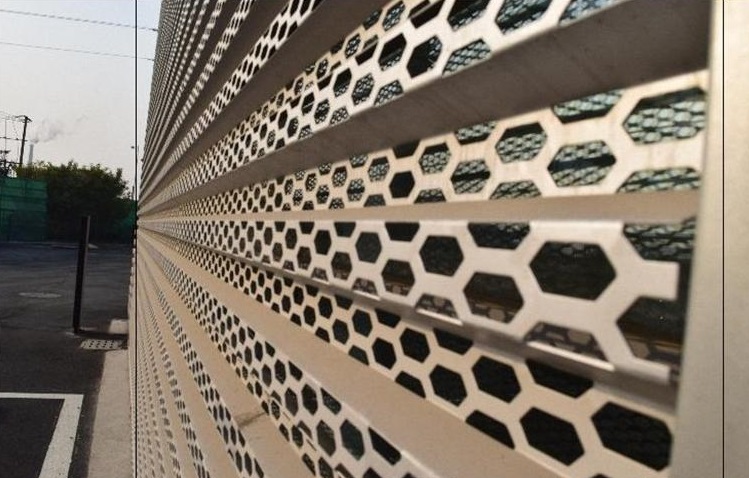

1. Drilling installation: According to the architectural design requirements, drill holes in the aluminum veneer and fix it to the structure of the building using screws and mounting brackets.

2. Sealing treatment: Professional sealing strips are used to seal the joint between aluminum veneer and buildings to prevent water vapor and dust from infiltrating.

3. Quality inspection: Finally, the installed aluminum veneer undergoes quality inspection to ensure that its appearance is perfect, safe and sturdy, and meets the design requirements.

5、 Summary:

The manufacturing process of aluminum veneer includes four aspects: raw material preparation, processing and forming, surface treatment, and installation. By selecting appropriate aluminum alloy materials, precise processing and forming, as well as high-quality surface treatment and installation processes, high-quality aluminum veneer products can be produced to meet the needs of architectural design and provide beautiful and durable facades for buildings.

Customer service QQ

Customer service QQ