Industry information

Company News

- Aluminum veneer curtain wall, the new darling of modern architecture?

- Aluminum veneer customization, creating personalized space and new fashion!

- Curtain Wall Aluminum Veneer: The Gorgeous Coat of Modern Architecture

- Aluminum veneer: understated luxury in modern architecture

- Fluorocarbon aluminum veneer: the "fashion pioneer" in the aluminum industry

Industry dynamics

- Characteristics and application fields of arc roller coated aluminum veneer

- The production process and characteristics of wood grain punched aluminum veneer

- Exploring Hyperbolic Aluminum Veneer: The New Favorite of Architectural Art under the New Trend

- Aluminum veneer: the secret weapon of architectural aesthetics

- Aluminum veneer: the beauty of architecture, the charm of metal

Frequently asked questions

- What are the applications of aluminum veneer in the interior decoration industry?

- How is aluminum veneer produced and manufactured?

- What issues should be noted during the processing of aluminum veneer?

- What are the applications of aluminum veneer in the construction industry?

- How to apply aluminum veneer in construction and interior decoration?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and quality control of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 7, 2025 21:39:29

- Click:0

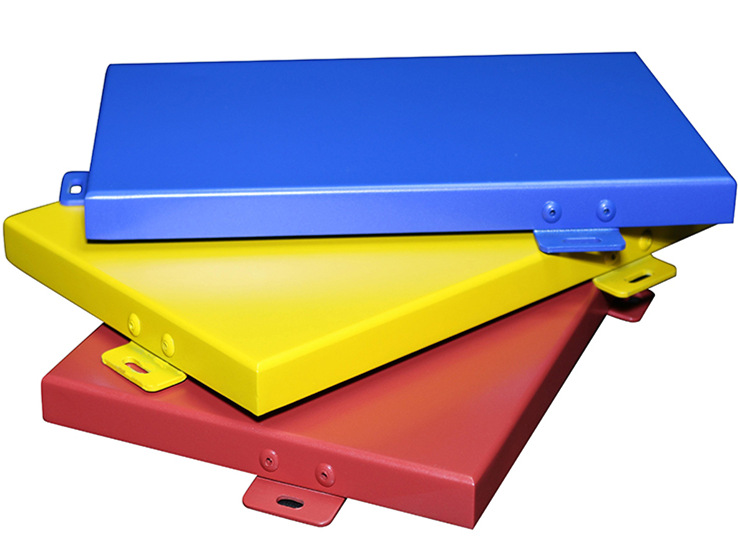

Aluminum veneerAs a common exterior wall decoration material, its quality directly affects the appearance and service life of buildings. High quality aluminum veneer materials must come from standardized production processes and strict quality control systems. Below is a detailed introduction to the production process and quality control of aluminum veneer.

The production process of aluminum veneer mainly includes raw material procurement, cutting, rolling, spraying and other links. In the raw material procurement stage, it is necessary to select aluminum alloy materials that meet national standards and ensure that the composition and content of the materials meet the requirements. In the process of opening and cutting, professional equipment and technology are required to ensure that the size and shape of the aluminum veneer meet the design requirements. In the rolling and spraying process, advanced production techniques and technologies are required to improve the strength and corrosion resistance of aluminum veneer, while ensuring that the decorative effect meets the requirements.

The quality control of aluminum veneer needs to be carried out from multiple aspects. Firstly, quality control of raw materials requires chemical composition analysis and physical property testing of the purchased aluminum alloy materials to ensure compliance with national standards. Next is quality control during the production process, which requires strict monitoring and testing of each link to ensure that the size, shape, strength, and decorative effect of the aluminum veneer meet the requirements. Finally, the quality control of the finished product requires comprehensive inspection and testing of the aluminum veneer, including surface treatment, strength testing, corrosion resistance testing, etc., to ensure that its quality meets the standard requirements.

In order to further improve the quality and performance of aluminum veneer, it is necessary to strengthen technological and management innovation. For example, advanced production processes and technologies such as laser cutting, CNC rolling, etc. can be adopted to improve the production efficiency and accuracy of aluminum veneer; We can establish a comprehensive quality management system, including ISO9001 quality management system certification, ISO14001 environmental management system certification, etc., to improve the management level and service quality of the enterprise.

The production process and quality control of aluminum veneer is a complex and rigorous process that requires comprehensive evaluation and control from multiple aspects. Only by selecting high-quality raw materials, adopting advanced production processes and technologies, and establishing a sound quality management system, can high-quality aluminum veneer materials be produced, providing better guarantees for the appearance and service life of buildings.

Customer service QQ

Customer service QQ