Industry information

Company News

- Aluminum veneer curtain wall, the new favorite of "soft decoration" in architectural art

- Aluminum veneer new fashion: the "silver decoration" revolution of modern architecture

- Hyperbolic aluminum veneer: the fashionable new favorite of modern architecture

- Aluminum veneer curtain wall: the magnificent coat of modern architecture

- Aluminum veneer customization, creating your exclusive art space

Industry dynamics

- Aluminum veneer: creating a "fashionable outerwear" for modern architecture

- Aluminum veneer design inspiration sharing

- Aluminum veneer, the finishing touch of architectural aesthetics?

- Aluminum veneer: the hidden 'warrior' in architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Frequently asked questions

- How is aluminum veneer produced and manufactured?

- What are the applications of aluminum veneer in the construction industry?

- What are the applications of aluminum veneer in the interior decoration industry and how can they be improved?

- What are the types of aluminum veneer?

- What are the applications of aluminum veneer in the interior decoration industry?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of the production process of aluminum veneer and its advantages in use

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 8, 2025 01:35:48

- Click:0

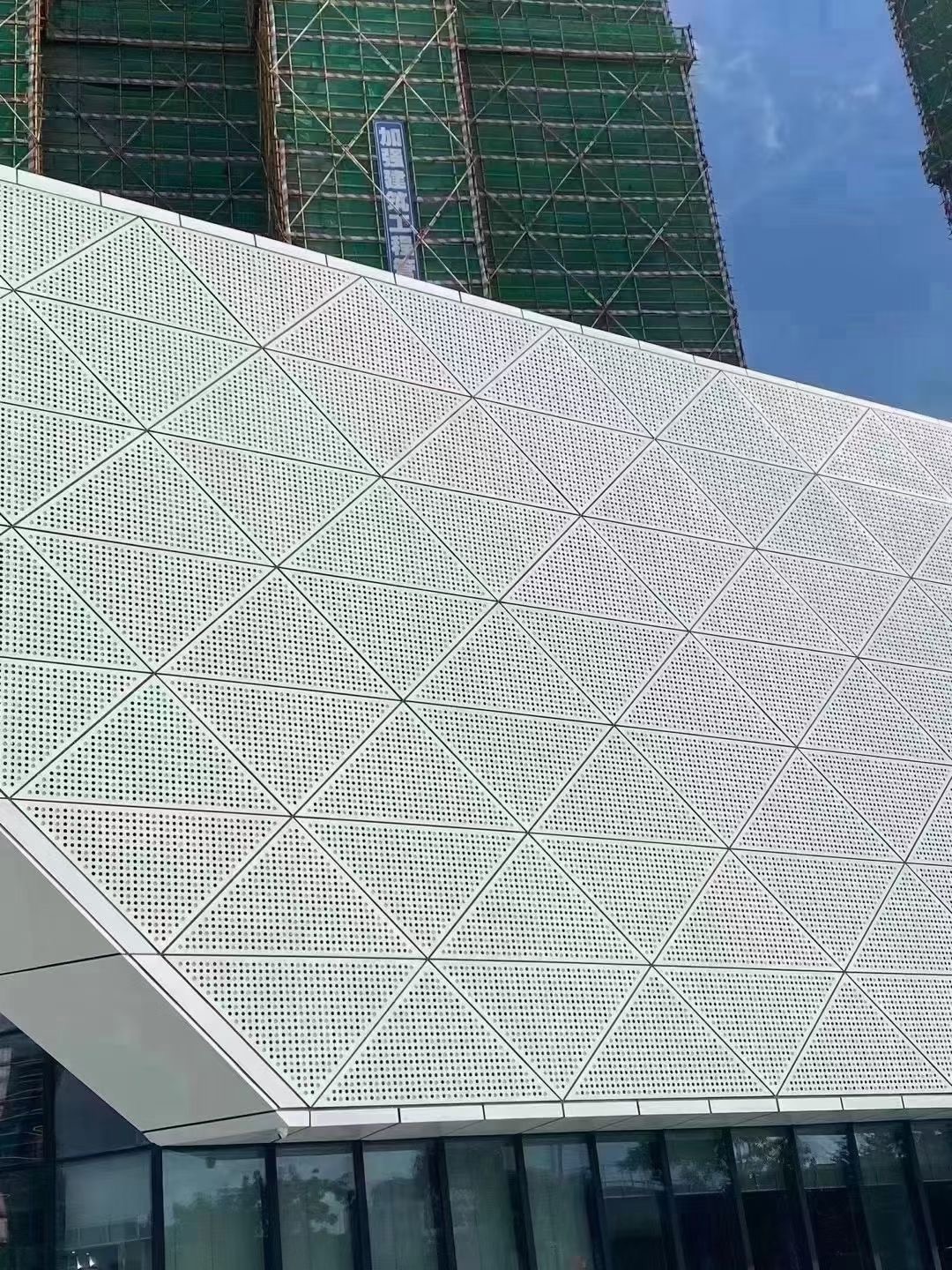

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, corrosion resistance, sound insulation, etc., and is highly favored in the construction industry. Below, we will provide a detailed introduction to the production process of aluminum veneer and its advantages in use.

The production process of aluminum veneer includes raw material procurement, cutting, drilling, spraying and other links. Raw material procurement is the foundation of aluminum veneer production, and high-quality aluminum alloys need to be selected as raw materials. Kaiping is the process of processing raw materials into flat plates, which requires the use of professional equipment and technology. Cutting is the process of dividing a flat plate according to design requirements, requiring precise control of size and shape. Drilling is the process of connecting aluminum veneer with fixed components such as keel, and it is necessary to ensure the accurate position and size of the holes. Spraying is the process of coating the surface of aluminum veneer, which requires the selection of appropriate coatings and processes.

Aluminum veneer has multiple advantages in use. Aluminum veneer has the characteristic of lightweight, which can reduce the self weight of buildings and lower the structural cost of buildings. Aluminum veneer has the characteristic of high strength, which can withstand large loads and impact forces, ensuring the safety and stability of buildings. Thirdly, aluminum veneer has the characteristic of corrosion resistance and can be used for a long time in harsh environments without corrosion and aging. Fourthly, aluminum veneer has the characteristics of sound insulation and thermal insulation, which can effectively prevent the propagation of sound and heat, improve indoor comfort and energy efficiency. Aluminum veneer can also be customized according to different design requirements and decorative effects to meet the needs and requirements of different customers.

Aluminum veneer, as a new type of building material, has the advantages of lightweight, high strength, corrosion resistance, sound insulation, etc., and has been widely used in the construction industry. By optimizing the production process and improving product quality, the market competitiveness and market share of aluminum veneer can be further enhanced. Both investors and production enterprises need to closely monitor the new technologies and trends in the aluminum veneer industry, adjust their business strategies and investment directions in a timely manner, in order to seize market opportunities.

Customer service QQ

Customer service QQ